Marty , are you using Alumilite regular resin for this part and do you do it in one pour ? This car is coming out great again as usual , fun to follow .

Yes, it is Alumilte Regular. And the big piece is one pour.

Who is Marty?

Wow , brain fart . It was a long day .

Hehehe!

Come on Mike I didn’t think you were that old!

(http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-smile.gif)

Sometimes I wonder if i’m loosing it . (http://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-sealed.gif)

I had this idea to use an RC car shock to make the action on the cushioning device smoother. All the shocks I could find on-line (that had dimensions listed), were too big to fit in the center sill. So I figured I’d try experimenting with mounting the shock inside the car body… sounded like a good idea in my head, until the shocks I ordered came in.

(http://burlrice.com/_LS_PS50.5boxcar/underframe8.jpg)

The springs are way to stiff for what I want, but I can take them off. The problem I don’t know how to solve right now is that the shock wants to stick if it has set in the same position for a while. After it has been moved, it doesn’t take near as much pressure to overcome the static friction on the shaft.

I’m not well versed in RC shocks. Does this behavior sound normal, or is it a consequence of buying cheap shocks?

I am working on the patterns for the car sides now. This gives me the opportunity to try some sheet metal ideas I’ve been stewing on for a while. I want to simulate dented ribs on the car sides.

First, a casting made from a 3d printed pattern:

(http://burlrice.com/_LS_PS50.5boxcar/rib1.jpg)

I mounted this to a flat piece of plastic, surrounded the edges with masking tape, and poured resin over it. Note: I sprayed on a thin coat of mold release before I poured the resin:

(http://burlrice.com/_LS_PS50.5boxcar/rib2.jpg)

The result above got another coat of mold release, then I poured more resin on top to give me a positive copy:

(http://burlrice.com/_LS_PS50.5boxcar/rib3.jpg)

With a positive and a negative resin copy, I sandwiched some .003" copper sheet between the pieces and pressed them together by tapping with a rubber mallet. I didn’t do anything to account for the thickness of the copper sheet. With the resin stamps being less than 24 hours old, they were elastic enough they did not crack. (I don’t know if this will hold true after more time passes). After I trimmed the metal pieces, I lightly distressed them by tapping with a small metal rod. These get mounted on a backer board, and another mold made. Note: I backfilled them with resin to make them easier to glue & handle after the distressing:

(http://burlrice.com/_LS_PS50.5boxcar/rib4.jpg)

Here you can see the result in the new resin castings:

@R/C shocks, I’m not sure if I follow exactly what your saying is wrong with them but as far as I know r/c truck shocks ride a full droop and really only dampen up travel. They dont work exactly like a car shock and use the spring to help dampen and force the shock back out. There an oil shock, you need some type of gas charged shock. Working with cushion under frame cars I can tell you thats probably a fair representation. A third of them don’t work as advertised anyway. If you use a spring you could probably get by with one spring that forces the draw head all the way out when not under force and will stay bunched when bunched. If the shock could slowy push out to full extention, it would be ideal but I gather thats what your saying won’t happen?

What I’m saying about the shocks is that on the first hit, it takes a lot of force to get them to move. After that, they’re smoother. I’m wondering if its worth the effort to try a different brand, or will it really make that much of a difference in the finished product anyway?

My brass parts came in today. I couldn’t resist but to put some of them together.

(http://burlrice.com/_LS_PS50.5boxcar/plugdoor1.jpg)

(http://burlrice.com/_LS_PS50.5boxcar/plugdoor2.jpg)

More work on the side patterns. I made the “oil canned” panels by pouring resin over polypropylene sheet, which was on top of a cardboard cutout about the size of side panel on the car. It took a little experimenting, but here is how it came out.

Before trimming:

(http://burlrice.com/_LS_PS50.5boxcar/side1.jpg)

After gluing in place, and trimming. The bottom sill was also added:

(http://burlrice.com/_LS_PS50.5boxcar/side2.jpg)

The gusset detail at the corner of the doors was built up with two layers of HVAC foil tape. Rivets are embossed in sheet styrene, then transplanted by slicing off with a flat-tipped X-acto blade:

(http://burlrice.com/_LS_PS50.5boxcar/side3.jpg)

The ribs get glued on next. Previously, my issue with this is that the wavy-ness in the panel allows a small gap under the rib in the low spots. This let RTV seep in, which had to be trimmed off later. This time, I tried filling in the small gaps with unsanded (shower tile) grout:

(http://burlrice.com/_LS_PS50.5boxcar/side4.jpg)

Here’s a shot of the whole side. The plug door car has some modifications to some of the ribs (the bottom ends are crimped), so I will mold this and make two more masters out of it - hence, the missing ribs to the right of the door:

(http://burlrice.com/_LS_PS50.5boxcar/side5.jpg)

After priming:

(http://burlrice.com/_LS_PS50.5boxcar/side6.jpg)

Cool. Finally, some who realizes and tries to model side panels that aren’t as smooth as glass.

Dave (Maynard),

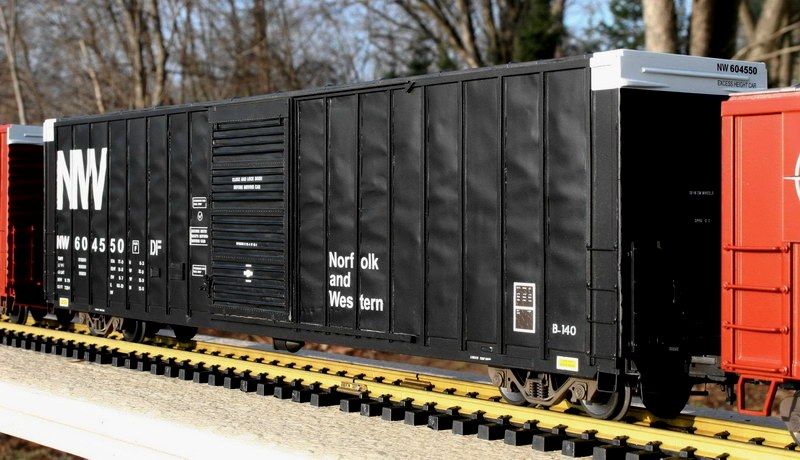

Burl has been modeling wavy sided cars for many years now. This is one of his kits I built over 5 years ago

Oh, now that is just too cool.

Wow Brian, that High cube of Burl’s is beautiful!

Finished putting together the first batch of couplers this weekend. They still need springs to simulate the end-of-car cushioning device, as well as blackening, but I think I have most of the work behind me now.

Finally got back to pattern making last week. I accidentally made the 3d print of the ends too narrow. I guess I just wasn’t seeing how it would go together in my head. The lack in width was the same dimension as the thickness of the car sides. It was no problem to chop up a couple castings and splice, but it took several days to do. I also had to do a little trimming on the pattern for the sides (slightly too long), but overall I’m pretty happy with the way the body is coming together:

Ran out of sunlight before I was ready to take a picture:

(http://burlrice.com/_LS_PS50.5boxcar/body3.jpg)

I think I am going to redo the roof mold. I wasn’t happy with the amount of work it took to get the ribs to line up, and I think I can do better.

Whether or not anyone else is interested in this, I don’t know… but I have finally solved something that has had me stumped for a while. My initial approach to making the roof was to cast it in two, long halves, and a mounting slug, as you can see from the pattern here:

(http://burlrice.com/_LS_PS5077/roof1a.jpg)

(http://burlrice.com/_LS_PS5077/roof1b.jpg)

The idea was to make a slug for the roof with the correct angle for the peak, and the thinner (.040”) roof detail would get laminated to that. I thought, since I 3d printed the panels & ribs, that there would be sufficient precision to make them align. After assembling one, I realized this was not the case. Some of the ribs lined up, but the ones that didn’t had to be chiseled off and relocated. Because I made the pattern long-ways, if it was off a little, that error was doubled when the two halves were put together.

Further complicating the roof was the fact that it overhangs a on all four sides of the car. If there was no overhang, I would have been tempted to make this a uni-body car, and cast it in my rotational casting machine… but the overhang is too deep (and the roof itself too thin) to make an undercut of that depth in a uni-body mold.

Then it hit me, and I came up with this:

(http://burlrice.com/_LS_PS5077/roof2.jpg)

Now the ribs are sure to be aligned, and I lost the sharp angle that was on the end of the rib (from the previous approach) where air bubbles liked to stick during casting. This also uses less resin than my previous approach, so the car is less top-heavy.