Michael Kirrene said:

See? Not to be a wise cracker, but I told ya!

I have pin gauges at work, but don’t want to use one to pop out the hub, though it would be ideal. All I have laying around are screwdrivers and I can’t use those or I’ll damage the plastic hubs. Down to the hardware store I go tomorrow to find some kind of rod or something the right diameter of the hub to pop out the hub. Last couple I tried had no flash at all on the hub or in the hole. Either the hole in the wheel is not true or the hole in the hub isn’t true. Maybe I’ll see if I can get some spare hubs from Bachmann to eliminate one of the two variables. Or ask David to fix them - he seems to know the secret. Out of the four axles I put on my Corona Beer car last night, I had to reject one because a wheel wobbled. Lucky me got 3 out of 4 good ones!!

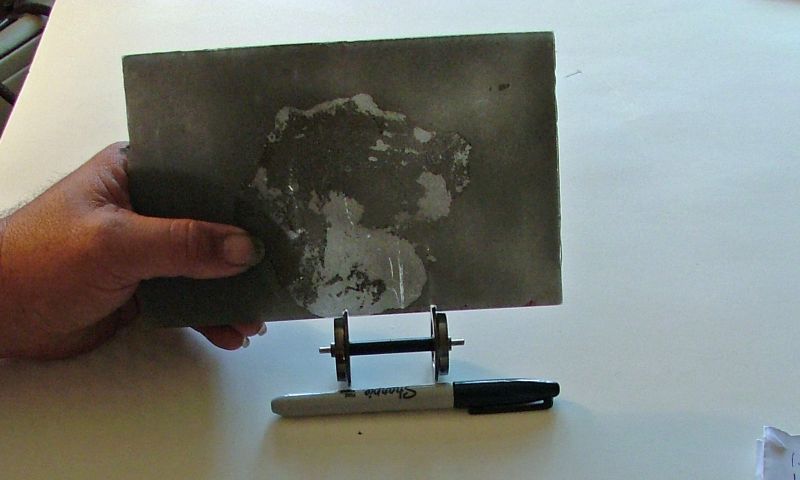

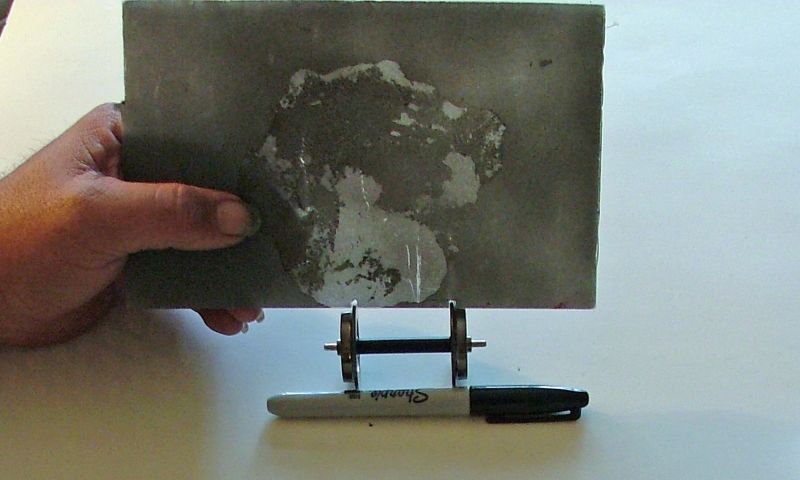

Broken and dull drill bits can be cut down and make excellent push pins. Most can be tapped with a hammer.

They also make strong hinge pins.

John