A few words for caution to all when working on old LGB engines.

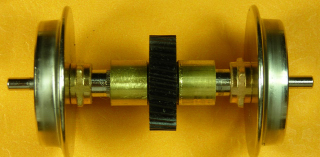

There are 4 different types of motors made (both in short and long shaft versions).

The first one was used in the ‘growler’ back in the 70’s. When running this engine was very noisy and ‘growled’ hence the name.

Next are the 2 with the red and black removable brushes. First one had a shaft that moved back and forth hence the ball bearing at the end of the shaft in the motor block. these are needed or the motor will fail (keep the ball bearing in place with a dab of grease when working on these.

2nd black/red brush units did not have the lateral shaft movement and the ball bearings must be removed or motor damage can occur.

Lastly is the newest sealed motor without the removable brush assembly. No ball bearings needed for this motor either, remove them if present.

Also note that some of the older engines had a motor with the non brush end with a shorter mounting end. I found these in an original 2085. I had a friend turn the motor on his lathe to make it fit.

If you do not do this, the motor will not fully mesh with the plastic gear and eventually strip the gear.

So, I always check the shafts of motors for lateral/end to end movement and the motor ends to be identical when changing them out.