From the “Everything is a Project” Dept. - today’s plan was to build a jig, start cutting timbers and start assembling bents. Well; I did get the jig done

To build the jig, I wanted to use my pin nailer. My compressor hose has been leaking a lot at the couplings, causing it to run too often. I decided to fix that first since I have a fair stock of couplings and adapters. Well, I guess when my youngest was making snow with it 11 years ago, he must have been trying to tighten up the couplings because the hex flats on the hose were rounded off and the couplings torqued to about 150 Ft. lbs! After much cussing and creative mis-use of tools I got them apart and eventually got the hose to sit under pressure without leaking.

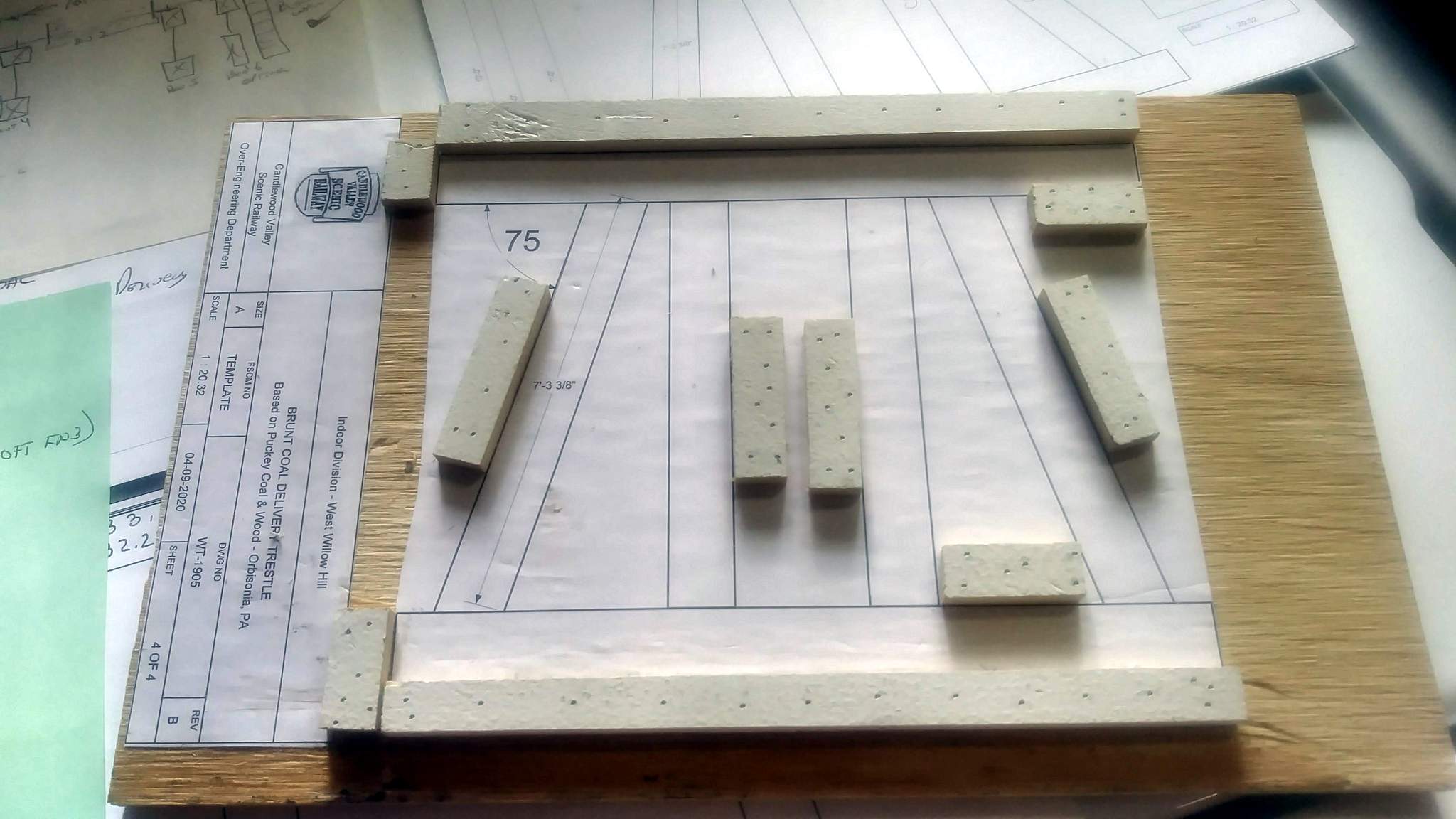

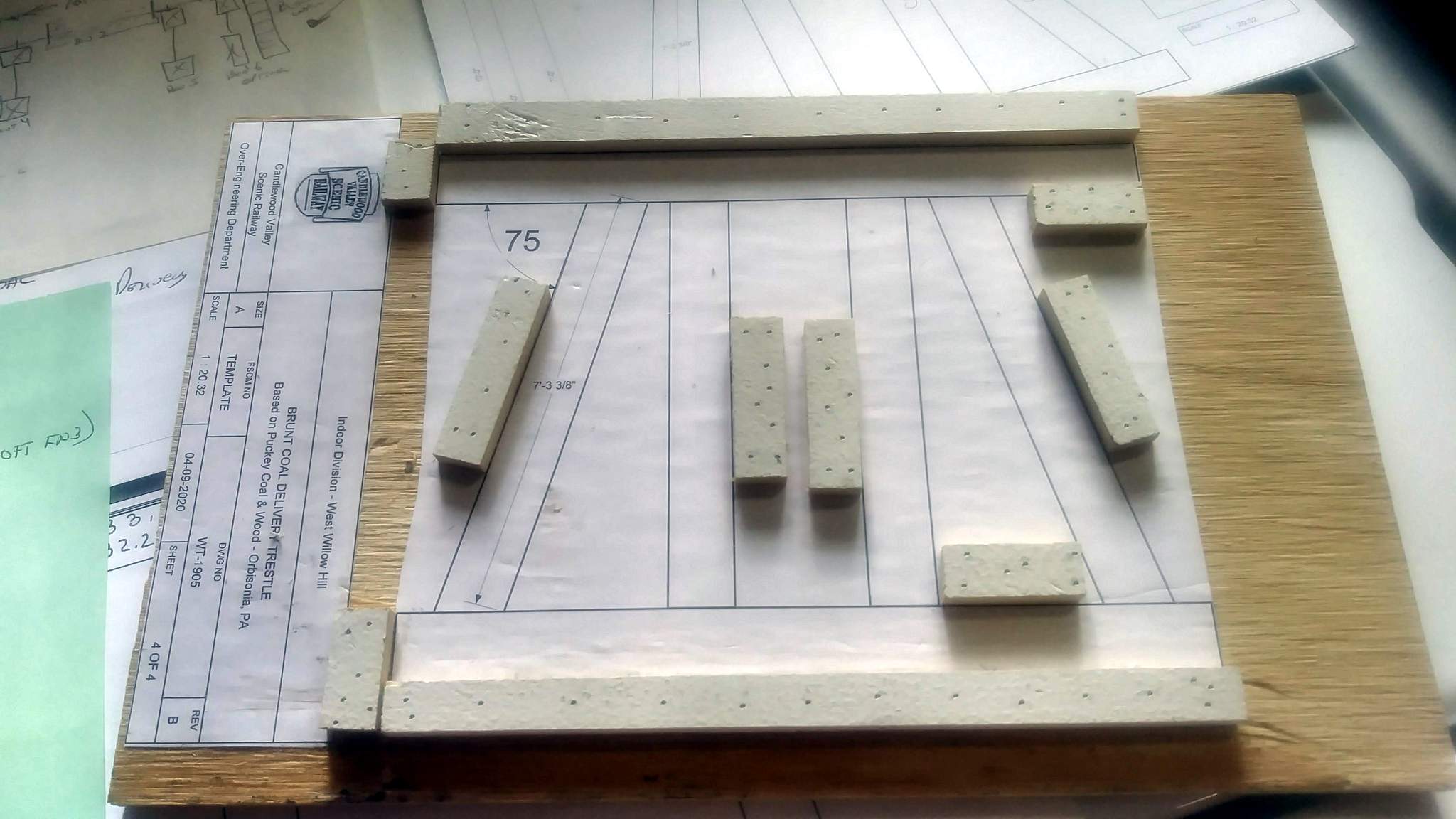

So now it’s after 3 and I’m finally ready to start the jig. I had some 3M spray adhesive on hand that I used to mount a full scale print on a hunk of plywood. Then I glued and pin nailed some 1/4" thick drops from the BOX Tunnel Portal project as blocks on the jig. This material is thin enough that I will be able the get my nailer in to tack the bent together while glue dries. Nearly finished jig…

I say nearly finished because that drawing assumes the timbers are a perfect 15mm square. Well, they were cut by hand on a entry level Craftsman table saw with a flimsy fence, so no; they are not perfectly square nor are they a consistent size. Thusly, (look it up Roo) I removed that top block before the glue set so I can adjust to make a perfect height bent with my imperfect timbers.

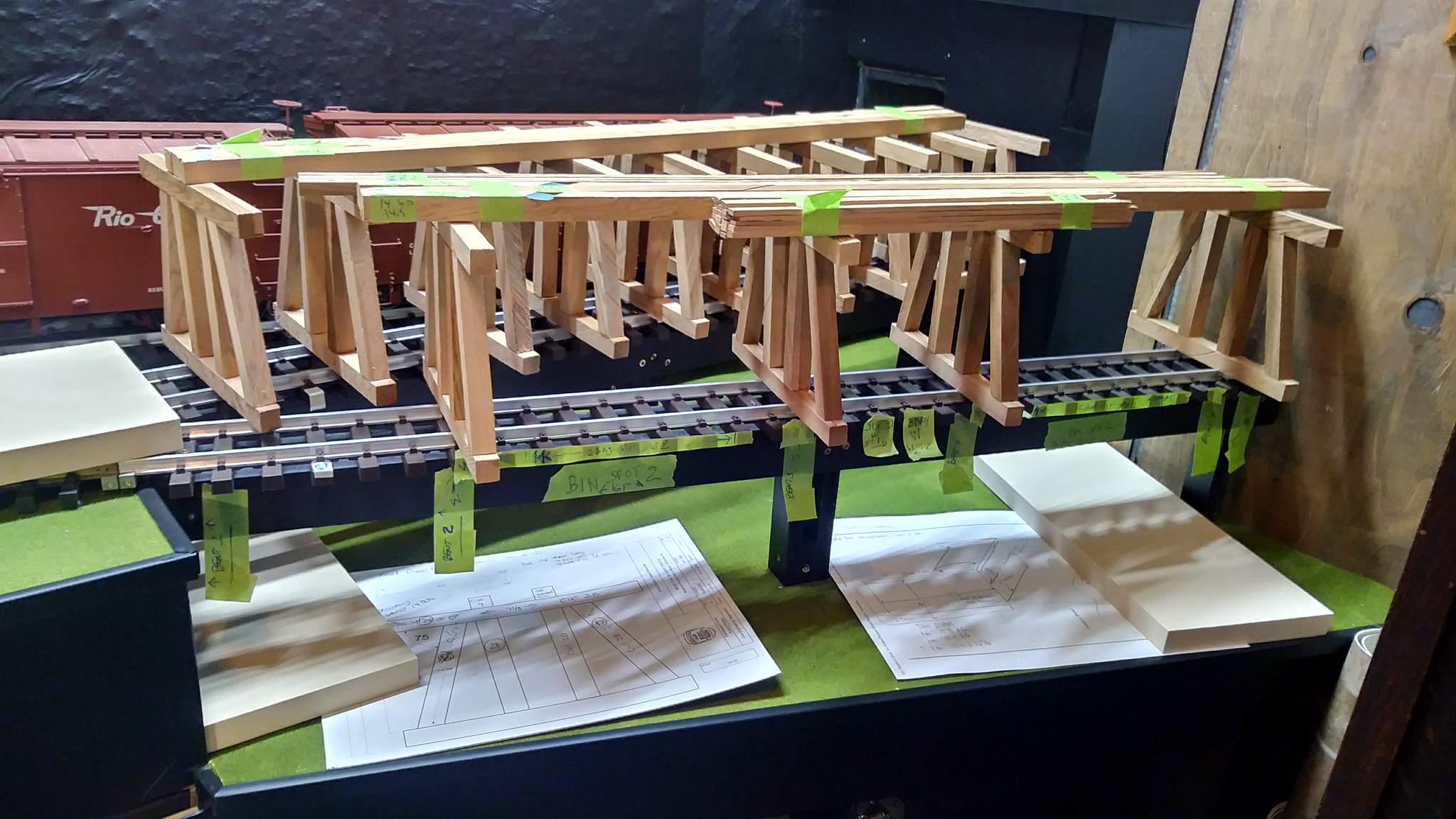

The rest of the day was spent with the digital micrometer measuring each 12x12 timber on two axis and both ends and logging the result after numbering each timber. Tonight I will go over that list and pick the most consistent ones to use as the top stringers. That way I can determine how high the bent needs to be so it meets up with my existing track.

Good thing there is no deadline for this project.