I’m a stickler for the used motor oil. Like the energizer Bunny it just keeps going.(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

David Marconi,FOGCH said:

I’m a stickler for the used motor oil. Like the energizer Bunny it just keeps going.(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

Which reminds me, I have to change the oil in the tractor…(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

Jason V. said:

Jon, Is that Indian ink and rubbing alcohol for the second cup in?

Yes. I used that on a tunnel portal for the indoor RR. Make a nice weathered grey look on cedar. For that particular project, an outdoor bridge, I ended up going with the ebony Minwax stain (first cup on left) mixed with linseed oil.

David Marconi,FOGCH said:

I’m a stickler for the used motor oil. Like the energizer Bunny it just keeps going.(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)

I like the look, but this is for indoors and I don’t want to be smelling it (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-yell.gif)

No photos, but I did rip up a bunch more of the 12x12 timber. I should now have enough to build at least 14 bents.

I also made a decision. Sean’s questions put my job sequence in the correct order. Before the trestle is assembled in place, faux retaining walls will be added at both ends. I have enough Signfoam scraps in stock to cut them up and get it done.

Opinion time!

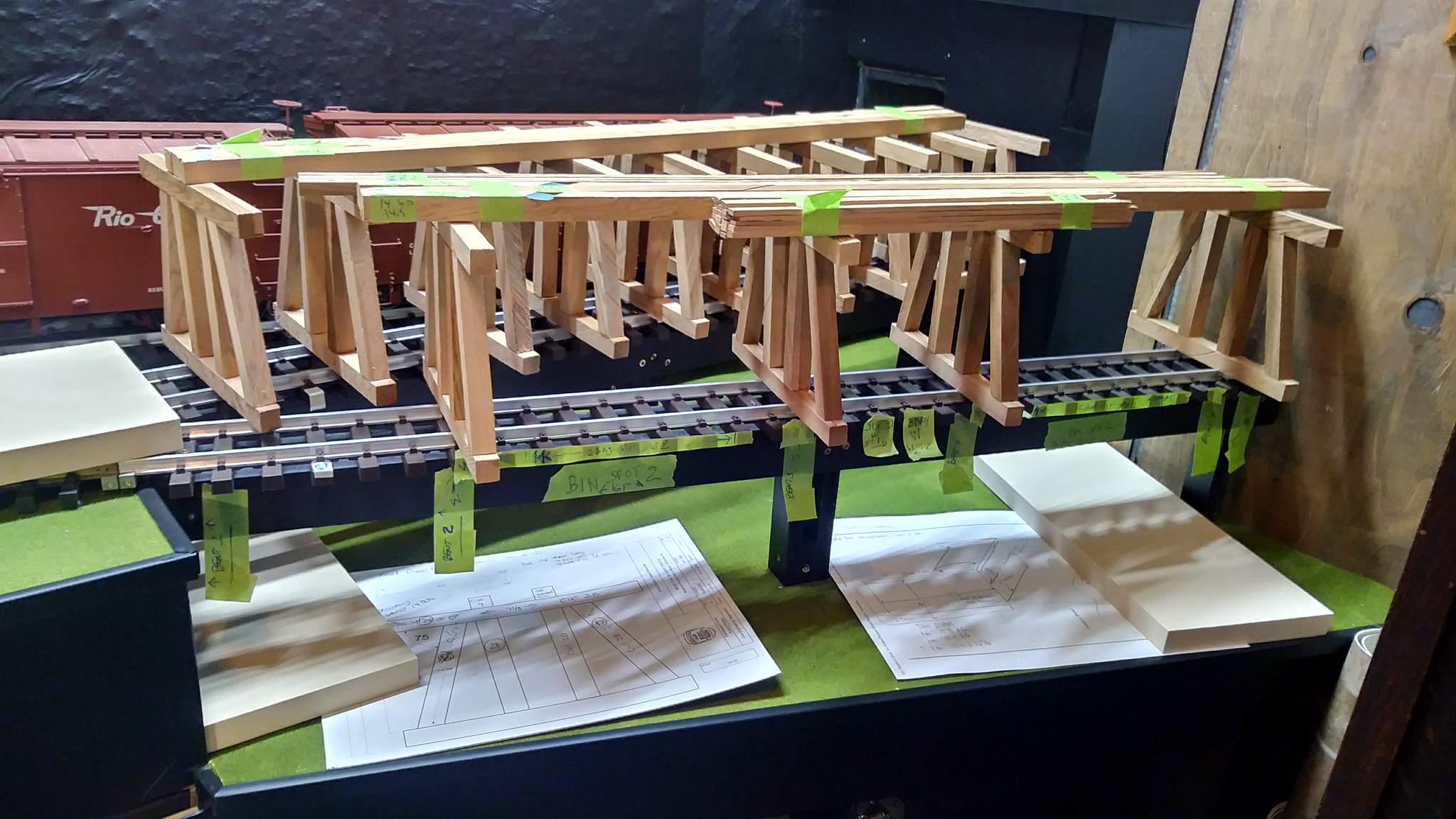

I finished cutting components and assembled the last of the 14 bents seen here in a possible configuration…

I also measured and cut panels for block retaining walls to hide some of the vertical surfaces. I’ve made these before in a number of different sizes. For BOX Tunnel, I chose very large 30" x 60" blocks so the work would go faster. My two color sample from that era is a smaller 16" x 32" block, and finally the new single color sample is 12" x 18" block…

The new one was colored with picked steel wool juice and hasn’t ‘matured’ yet. I helped it out with some charcoal and another wash with the juice…

I think the smaller block sizes work best in this area. I kind of like the rusty color; looks a little like sandstone. Y’all are welcome to chime in.

Going with the sandstone, myself. You can always tone it down if the contrast with whatever is near it is too much.

- Eric

I’m with Eric. Sandstone. But I’d suggest you add some more black near the coal bin to make it look covered with coal dust. I’m sure you knew that. (and Pete Thornton was that one that put this into my head)

Jon Radder said:

Soon after my indoor expansion at West Willow Hill was operational, the FEBT magazine Timber Transfer published an article by Ron Pearson on the Puckey & Co. Coal and Wood yard in Rockhill Furnace. The coal delivery trestle was a beefy wood structure with a few dump bins that remained extant under different names until the railroad closed in 1956. This structure is perfect for use as my Brunt Coal Co. delivery trestle.

The following two photos of Puckey & Co. stolen from the Timber Transfer article and used without permission. I will delete them if the copyright holder(s) objects…

The question is WWRD …What Would Ron Do?

I vote old school stacked limestone…only my opinion and knowing the area that peaks you’re interest

Rooster ’ said:

I vote old school stacked limestone…only my opinion and knowing the area that peaks you’re interest

Outdoors, using real stone; I would agree. Time I’ve got, but not the patience to carve a couple of thousand random shapes. But you have me thinking. I may have a sheet or two of those cut stones they used to sell at the big box store and several of us used as foundation or wall stone. This stuff…

I wouldn’t use it for everything, but maybe to cover the paneling wall on the right, under track level.

Retaining walls were started today. After removing the temporary trestle and track I fitted a few pieces of Sign Foam brand high density urethane foam to the spots to be covered…

Then I began the process of laying out the block. Since this will not be painted I avoid use of pencil or other markers. Lines are marked out using an Exacto by making some small punctures; then the lines are scribed in the foam using a variety of tools from an antique manicure tool to a couple of harbor freight pics…

Once the lines are done, I beat the foam using an dirty old wire brush. Banging the wires into the foam and dragging it around. No rhyme or reason. Just keep messing it up until it feels right…

This time around I’m trying Charcoal Pastels rather than India Ink to bring out some of the detail. I scrape the pastel with the Exacto randomly depositing black dust. I used a small stiff brush to spread the dust around then a light spray of alcohol before brushing one more time to spread it out. Sorry I didn’t get a better picture at this stage…

Once the alcohol evaporated; I used the same stiff brush to wash the entire surface with my Pickled Steel Wool solution that has been on my shelf for years. The color will change a little as the solution dries…

I still need to color one more section then decide what I’ll use on the right end of the trestle to hide the paneling. The vision in my head is a mounted photograph, but I may do something 3D below track level.

Does Marilyn know you use her washer as your work bench?..(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

Dang blocks are real close to the real thing. Nice work Jon (https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

Ken Brunt said:

Does Marilyn know you use her washer as your work bench?..(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

Well, she left it in the train room, so she has no choice! Besides, I have an Official Letter of Authorization from Mik !!!

(http://lsc.cvsry.com/Post2019/Basement19-B452.JPG)

Just use the pic that I found in the old thread …on the right … you already have it in position just slide it down onto a wall . .

Jon Radder said:

Ken Brunt said:

Does Marilyn know you use her washer as your work bench?..(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-wink.gif)(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-cool.gif)

Well, she left it in the train room, so she has no choice! Besides, I have an Official Letter of Authorization from Mik !!!

Struggling with a few more decisions before I paint the bents. Where the roadbed transitions to trestles, I’m not sure I like the closeness of the straight main line bents with the siding bents at the very start of the trestle. It can be seen in these two dry fit photos…

I’m thinking about building a single double track bent for just the first one. This is an actual size mock-up of the two track version…

I’m not sure I have enough 12x12 timber left to build the double wide, so that will weigh in on the decision. I don’t want to set up the table saw again to mill wood for just one bent.

I also need to make a final decision on color. The color photo of the prototype indicates that it was simply raw wood that had weathered to a grey color. I’m also really dig’n the test pieces I stained with my pickled steel wool (rust) solution…

The weather outside today is good for staining; so I need to decide soon If I’m going to start final assembly tomorrow.

Thats looking great Jon

I love the stone that came out nice

Pickled steel wool looks the best. And it continues or changes after Mother Nature takes over.

Jason