I love it so far !

Hope you don’t need to hit that clean out after the family was over for the Holiday.

I love it so far !

Hope you don’t need to hit that clean out after the family was over for the Holiday.

" Rooster " said:

I love it so far !

Hope you don’t need to hit that clean out after the family was over for the Holiday.

Ha! I’m banking on not having to use that for a loooong time. We put an addition on last year, and all the utilities go through that hole. Unfortunately, that stupid pipe runs down two walls of the basement. It was that or a pump.

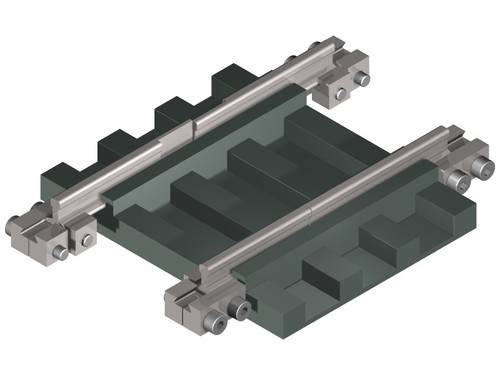

Eric, Curious, not criticizing, Why did you cut the rail on an angle like that? Did you do the same thing on the hinge side? Looks like it may be sharp enough to pick at plastic wheels or traction tires (if you use them). Also, do you have some way to stop the bridge from flipping over onto the track?

Dan- I have noticed that real drawbridge joints are cut this way, so I thought I’d mimic it. However, your point about catching plastic wheels and tires is a good one. I may sand off the sharp bits.

At the hinge side, I just cut them parallel to the edge of the bridge. The track is angled, so it’s not square to the rail, but the angle is minor.

The bridge hits the wall before it gets anywhere near the track.

The angle supposedly supports the tread better if the gap is not closed, like the transition from the wing rail to the frog in a switch.

But I would be concerned that pressure (lack of gap) might effectively cause a change in gauge.

I’d try thinning the rail in half, sort of like how the SJ expanding track sections work:

At this point, I’m not going to do anything (except perhaps smooth the edges) unless it fails. I left a bit of a gap to allow for potential expansion of the rail and/or benchwork in the summer. The bridge alignment is fairly precise, but not enough to mill the rail to half width and depend on an overlap that tight.

As always, I do appreciate the input. I will report back if it fails. As you can see in the video, the train runs across it very smoothly.

Yeah, it was more of a “next time” suggestion. Also in the basement, your expansion/contraction issues are waaaaay less than outdoors.

Greg

Looks great Eric. You made the right decision keeping the bridge as a single piece. While my curving / folded bridge has served well for a long time, as it ages the hinges get a bit sloppy and alignment at the opening end can be a bit tricky. Most of my locos don’t complain, just bump across, but my C-19 will derail the pilot truck if backed across the gap without making sure the rails line up perfectly.

I like what you’ve done, Eric.

Thanks, guys. This has been a blast so far.

Step 28 shove test

The shove test is a good way to find problems and you must have been confident of your work to run at that speed in reverse ! LOL

I like the diamond and how that track reconnects. You have lots of potential for RR excitement in that area.

I’ve closed the loop! Video:

You can now apply for a Roundy round rail road membership! (http://largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)