Well I did some more today…

I glued the entire building together yesterday. the joints are “mitered” that is to say cut at 45degrees. I just applied glue to the angled cut and taped the building together using blue masking tape. it was dry this morning so I could take the tape off. it seemed as stiff and strong as one would expect from styrofoam.

I had also cut a notch around the bottom edges of all the sides so that I could insert a plywood floor. this stiffens the whole structure and adds some heft to it so perhaps it will not blow away off into the woods!

The library in West Gouldsboro is whitewashed stucco. I thought i would try to replicate that. i tried just painting the styrofoam but that didn’t really answer. I needed something thicker with more “body” I decided to experiment. I added some titebond III to the mix, better but not yet, then I added some wood flour. Wood flour is a product we use with epoxy boat building, it is really only sanding dust say from a factory that makes doors and collects the dust from the sanding operation. It may actually be specially made as a Food additive believe it or not. I brushed it on quite libarally and left it with some texture.

that should take a while to dry…I turned up the heat a little in the shop.

So off to work on the stones. I visited my college last week, both boys are there now. the oldest school building is a stone structure from the 1860’s if memory serves. it uses cut stone just like the stuff from Taylor’s Quarry operation.

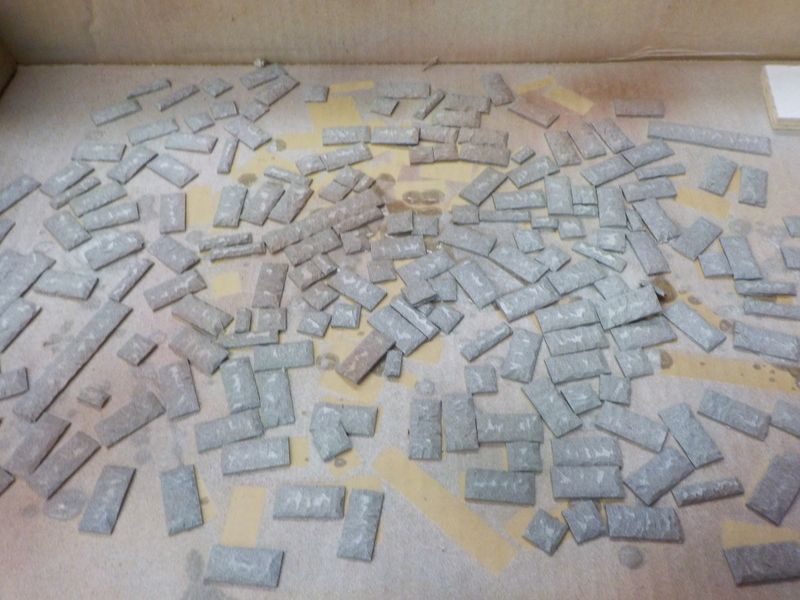

this is old granite. I love the colors and want to try to approximate the color and variations. I had made a stone train station using plastic decking planks sawn into blocks. worked well, looked like cut granite but it had no real variation in color. Mr Taylor’s product also has very little color variation so needs painting. because I want the blocks colors to vary a little I decided to paint them before application. I laid them out on a bit of cardboard and misted them with spray paint. I used several colors, dark gray, linen white, rusty primer and silver. I tried to mist them fairly uniformly with everything but the rust. the rust was misted onto areas so that some stones are quite red most are gray and some in between.

I grabbed some random stones to see how they looked. the large stones on the bottom are blocks sawn out of plastic decking.

the decking comes with grooves to accept the fastener system. I sawed off the bits making up the grooves to give me stone moldings.