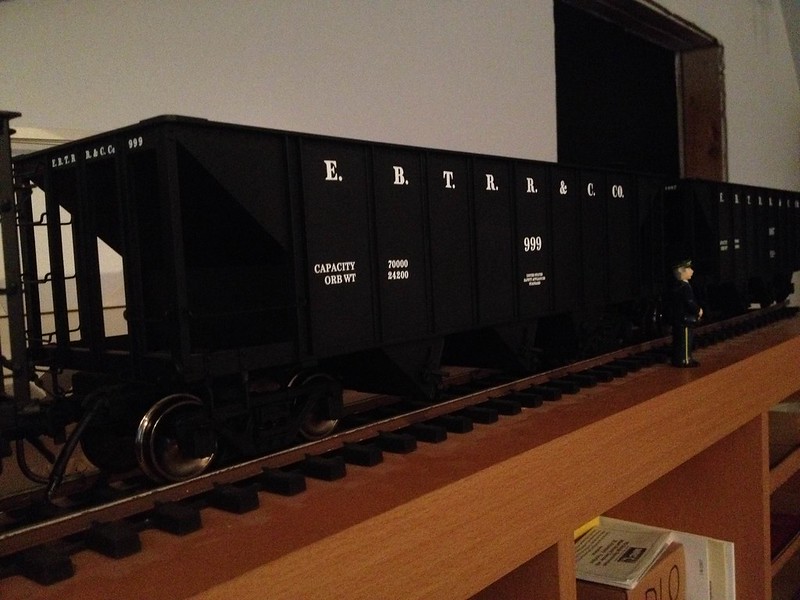

The purpose of this post is twofold. One to show how I have attempted this conversion, and two for seeing if anyone else has a better method or way to improve.

The stock couplers supplied with the Accucraft’s hoppers are full size. The EBT used 3/4 size couplers on their rolling stock. So taking the advice of many on this site, I got a hold of Accucraft’s 1:32 scale couplers which scale out perfectly for the 3/4 size ones that the EBT used. (Thanks John Bouck ! )

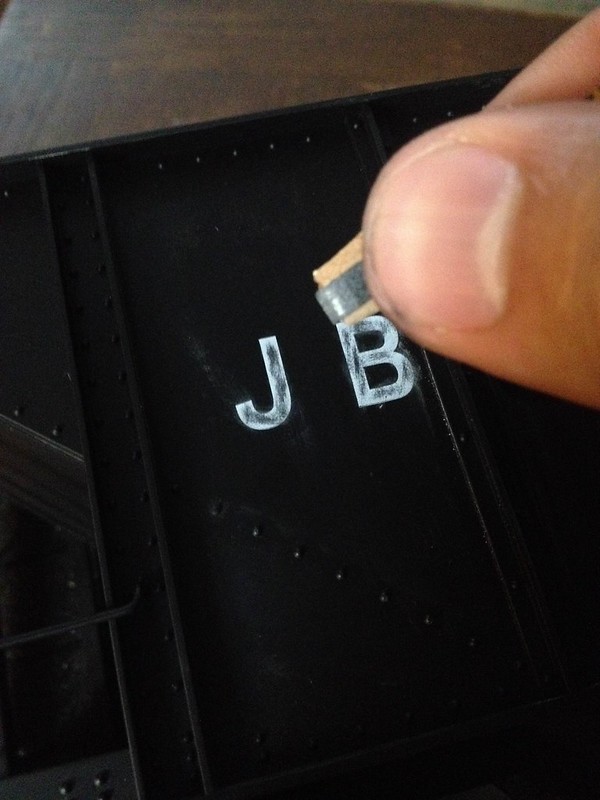

As seen in the picture, I cut the front of each side off of the draft gear box bottom. This allowed the bottom to fit down into the stock draft gear box top. I then used the screw that came with the hopper to bolt things down. The 1:32 scale gear box top was not used. This set up lets the coupler function just as it does in it’s normal draft gear box, with sprung side to side and forward reverse movement. The height above the rails also works out exactly as it should.

Over all I’m very pleased with the replacement. My only concern is it’s strength. The stock set up has 2 screws to counter the strain of pulling a long train. One from the top and one from the bottom. My arrangement only utilizes one. Will this be stout enough? Or, am I all wet, is there a much better way that I have missed?

The only other detail I need to work out is weather or not to neck down the end oft the cut lever to fit into the smaller pin hole on the 1:32 couplers or enlarge the hole. There isn’t much room for enlargement on those.