Update… I went ahead and sprayed with a matte clear coat. This gave it a very nice flat smooth finish with a few coats and sanding in between coats. Next step is pinstriping. I went to the craft section and checked for some pinstriping tape. Problem is they don’t have it in yellow and small like I need it. 1/16 and 3/16. So… I made some. Now time will tell how well this will work out and stick. So here we go…I bought a roll of yellow electrical tape in a package of 4 different colors. Now I had to figure out how I’m gonna cut this stuff and straight. It also needed a backing which when ya unroll tape it doesn’t have that. I took a piece of wax paper and cut into strips laid them end to end taped them together and then a strip of scotch tape for extra strength. Wax paper alone didn’t work. So now I have a backing that I can peel away as I apply it.

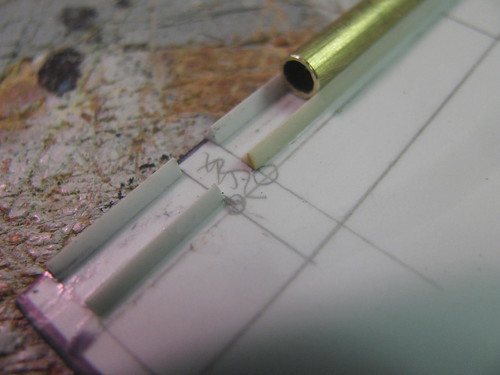

So under the strip of yellow electric tape is two layers, wax paper first, then scotch tape one piece. Next I taped this down and straightened out close and then took a straight edge to cut it so I had a straight edge to start with. Marked off what I wanted and cut.

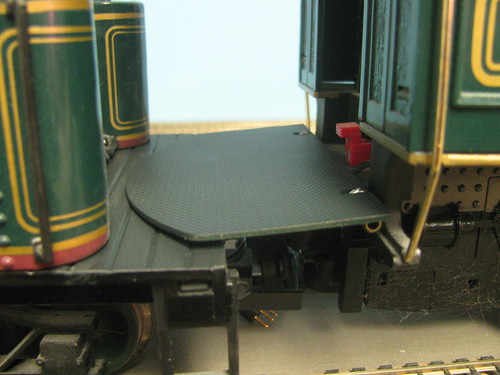

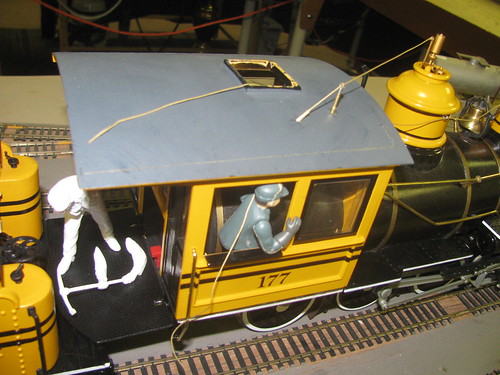

I had started and forgot to take progress pics up until I got this far, but you can see some of the strip that was cut in the pic laying by the exacto knife curled up. I cut these in approximately 2 ft pieces enough to have a tail to hang onto to work with. Being careful not to stretch it as I went along applying it to the body. After it is applied I noticed that it does allow some black to show thru, so it is a off yellow. I thought about doubling the tape up, however it would be pretty thick. So I went with it as is. Next issue is getting the lettering to match the striping. Still thinking on this. I am gonna check at Hobby Lobby for some vinyl sheets with adhesive backing. If they have the shade of yellow I need I will get a sheet and cut new pin stripes and have my wife do the lettering on her cricut cutter…

So overall this turned out pretty good. Now I am wondering if I should clear coat this again to help seal the pinstriping to the body?. What are your thoughts on this guys?. I will wait to do this if ya’ll think it will help until I see if I can get a yellow piece of vinyl sheet to cut everything out of it the same color and lettering. More to come later… Thanks for looking…