Greg Elmassian said:

Interesting, I see a term I was not really familiar with from the old days: “peak charging”… apparently instead of using the 2 different methods of peak charge detection (negative dv/dt on nicad and zero dv/dt on nimih), they just watch for the peak voltage… which should be fine, maybe a bit early on nicads.

Is this what you guys understand “peak charging” to be?

Greg

Greg,

Far as I know; peak charging is synonymous with dV/dt and or dT/dt charge algorithm’s. Either reaches a peak and terminates charge.

-dV/dt is best for NiCD’s, but can be problematic with NiMH yet is widely utilized and REQUIRES a NiMH peak charger… Intelligent micro-processor based chargers utilize said algorithms with additional gates i.e., timers, voltage plateaus. temperature thresholds, slopes and more, thus mitigating the problematic issues with NiMH (false peaking/over charging).

Additional thoughts:

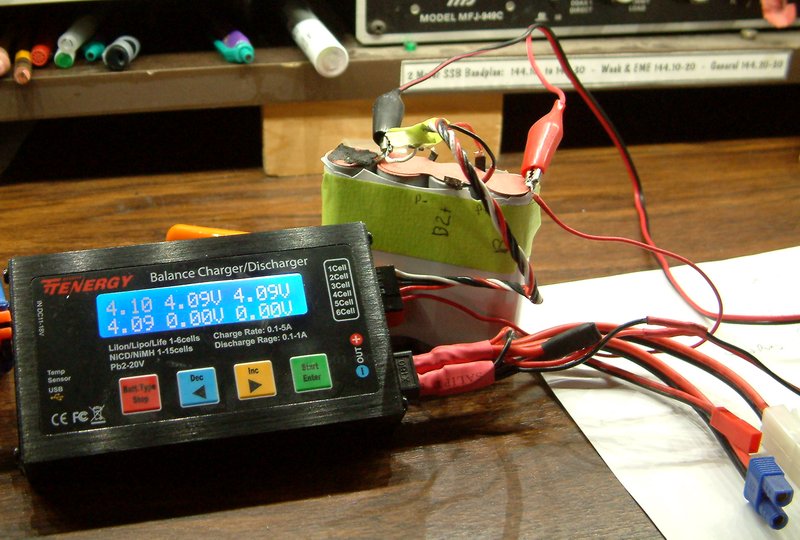

Smart charger refers to a charger that communicates with a smart battery. A “smart” or IC equipped battery at the very least identifies itself, its cells individually and suggests what algorithm to put to work. Lithium technology based chargers typically known as balance chargers are close as at it gets in our world to the best of my knowledge.

-dV/dt refers to the rate of change of voltage over time charging algorithm. As a Nickel battery is charged at constant current, the voltage increases, reaches a peak, thereafter the voltage dips slightly and charge terminates. So the charging circuitry looks at the rate of change of the voltage (or simply the change in voltage). When charging voltage starts to decrease, charging is finished.

dT/dt refers to the positive rate of change of temperature over time charging algorithm. An ancillary thermistor/sensor/probe is required and placed against the cells. Nickel batteries are charged at a constant current continuing all the way to charge termination. As the voltage increases (possibly even reaching a peak) and once the temperature threshold is reached the charge is terminated. The charging circuitry looks at the rate of change of the temperature (or simply the change in temperature).

CC/CV refers to a constant current, constant voltage charging algorithm. Charging begins with providing constant current to the battery, once the specified battery voltage is reached, charging switches over to constant voltage, topping off the battery. When the battery is topped off at a constant voltage, the charging current decreases as the battery is charged until it drops to a sufficiently low value and times out and or a voltage specification is reached and charge is terminated. All Lithium based chemistries must be charged in this manner, including LiFePO4 cells.

Lead acid batteries also charge by constant current, constant voltage.

Generally speaking all the aforementioned charge algorithms would work in harmony with a time-out (timer) safety function to limit MAX time under charge… These timers are often set for a default value; chemistry dependent, but often can be programmed to user defined parameters.

Michael