Burl, if you can give me a few weeks, I want to order a few of your brake wheels, so I’ll just have you add the hinges to the order when I place it.

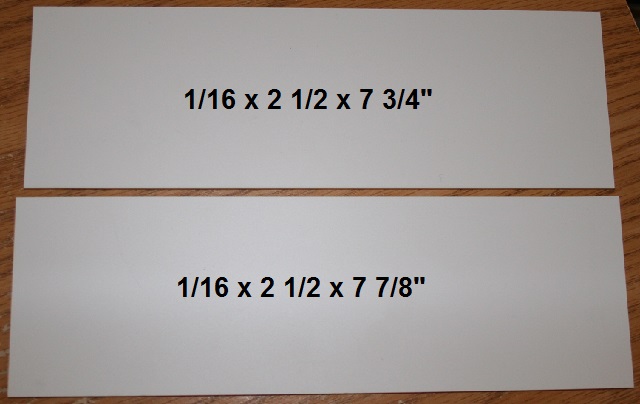

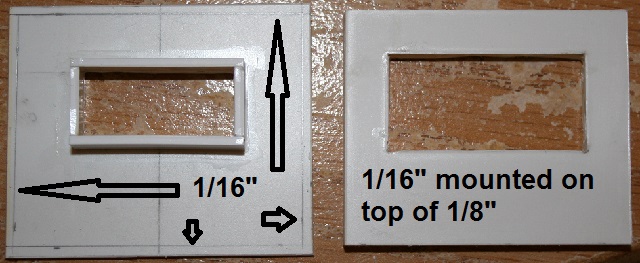

Okay Guys, we need some 1/16 " styrene and we’ll need the following:

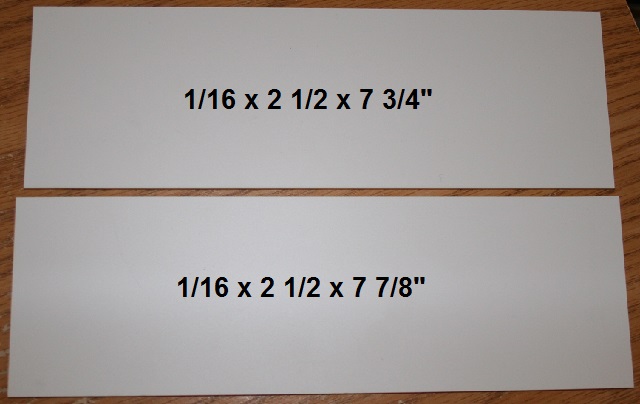

1 - 1/16 x 2 1/2 x 7 3/4"

1 - 1/16 x 2 1/2 x 7 7/8"

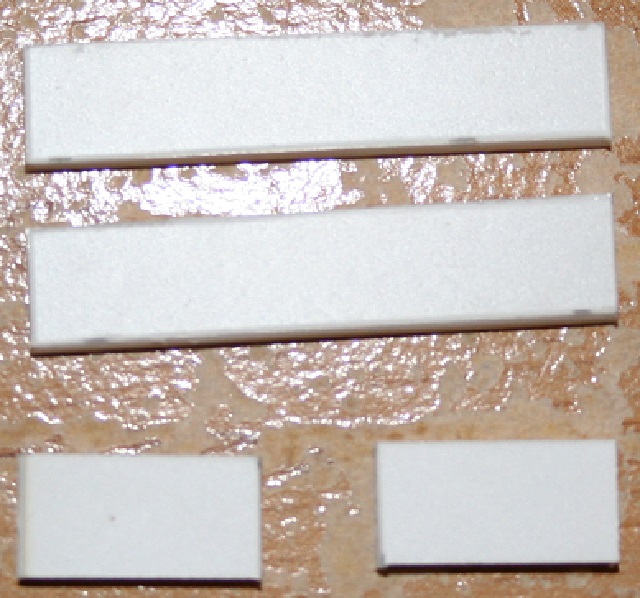

2 - 1/16 x 15/16 x 7 3/4"

2 - 1/16 x 15/16 x 7 7/8"

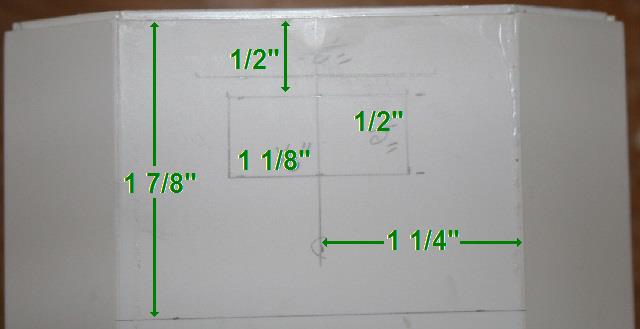

Take the three 7 7/8" pieces and mark lines 1/16" from each end.

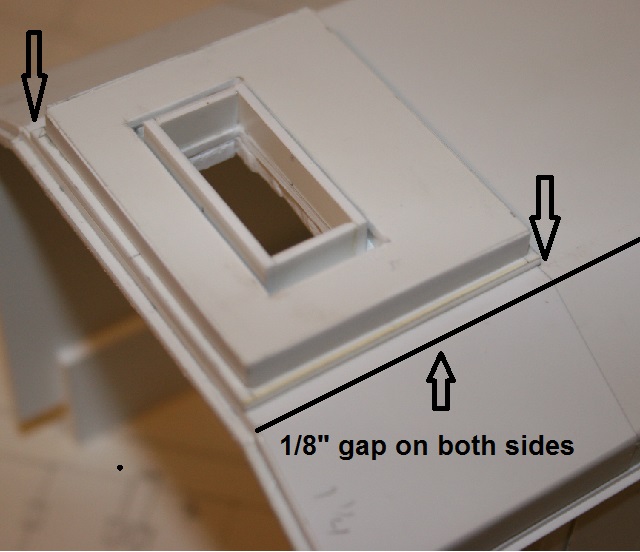

Glue the 7 3/4" pieces on top of the 7 7/8" pieces leaving the 1/16" gap at each end. Mark the end of each piece, and on the narrow pieces, mark a 30 on the center side and a 60 on the outside side.

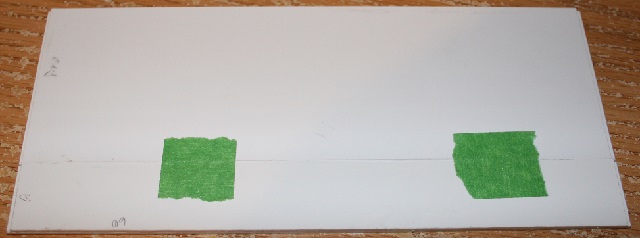

Put some tape on the bottom of the two narrow pieces leaving the 30 side exposed.

Flip them over and sand the edge at 30 degrees until you have a nice sharp edge. I did the sanding by hand. I initially tried with power, but couldn’t get the clean edge I wanted. By hand, I just ran it from side to side. It takes some time, but makes a nice clean edge. The tape protects the bottom while sanding. Remove the tape when done.