While I’m waiting for the Climax yoke, I dug out my B’mann and Accucraft coach wheel pickups. [I used batteries to light the coaches so the pickups were removed.]

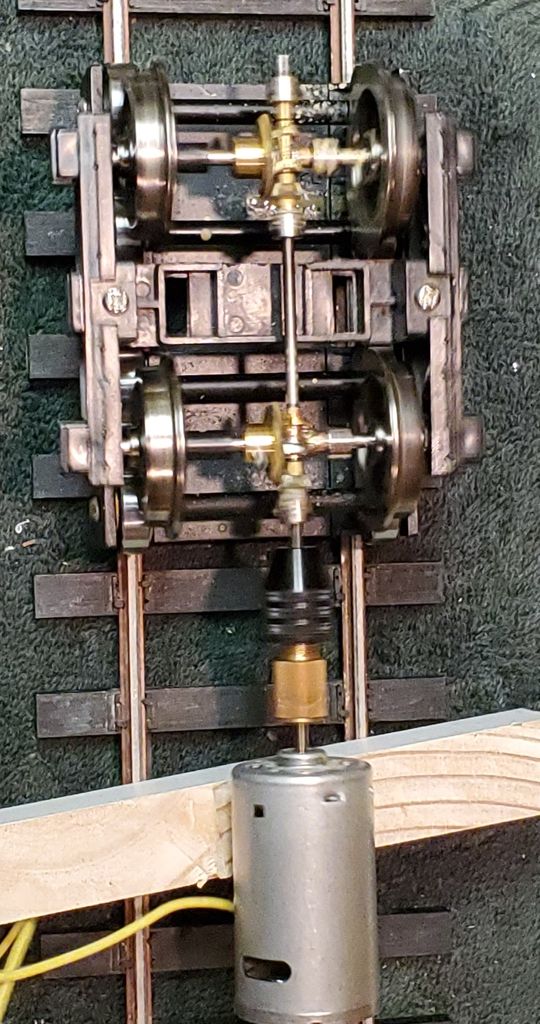

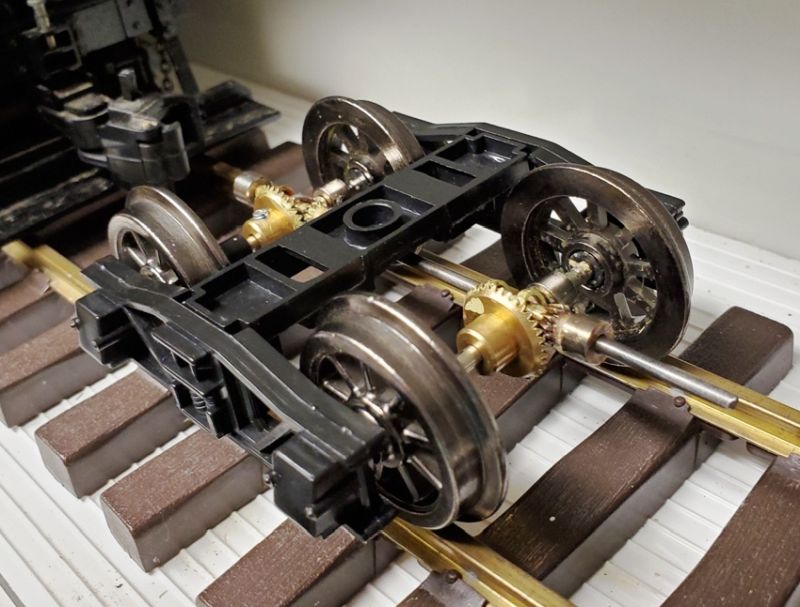

The front truck is a B’mann shortie truck, which they are currently selling for $8.40 complete with wheels. I added a pair of Accu pickups bolted to the crossmember.

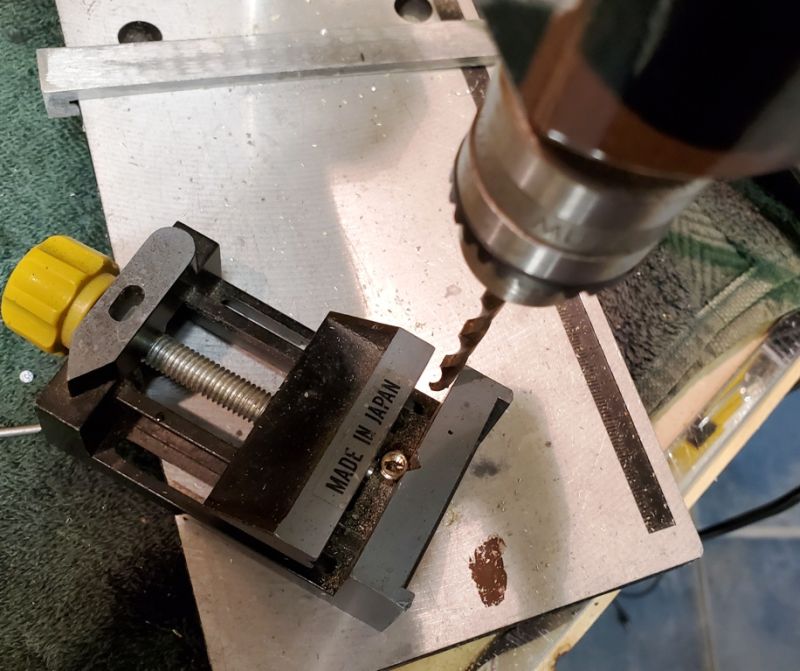

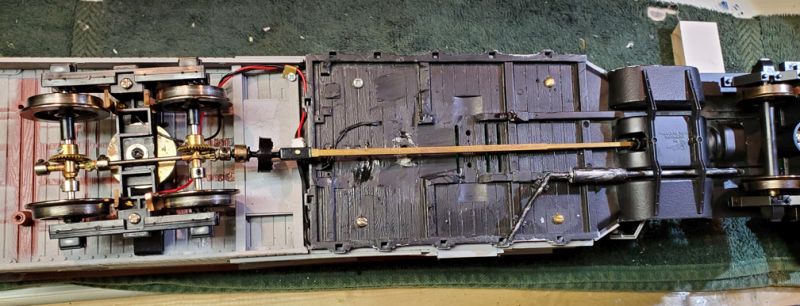

The bolts are now trimmed and will be painted. The wires are soldered to the pads under the front of the frame - the original used B’mann’s favorite sprung plungers, which I don’t have and don’t want.

The curly spoke wheels came from Jason at The Train Department. I think they are 7/8ths scale, but it occurred to me that I could trim the axle ends and make a cute inside frame front truck. Maybe next time. . .

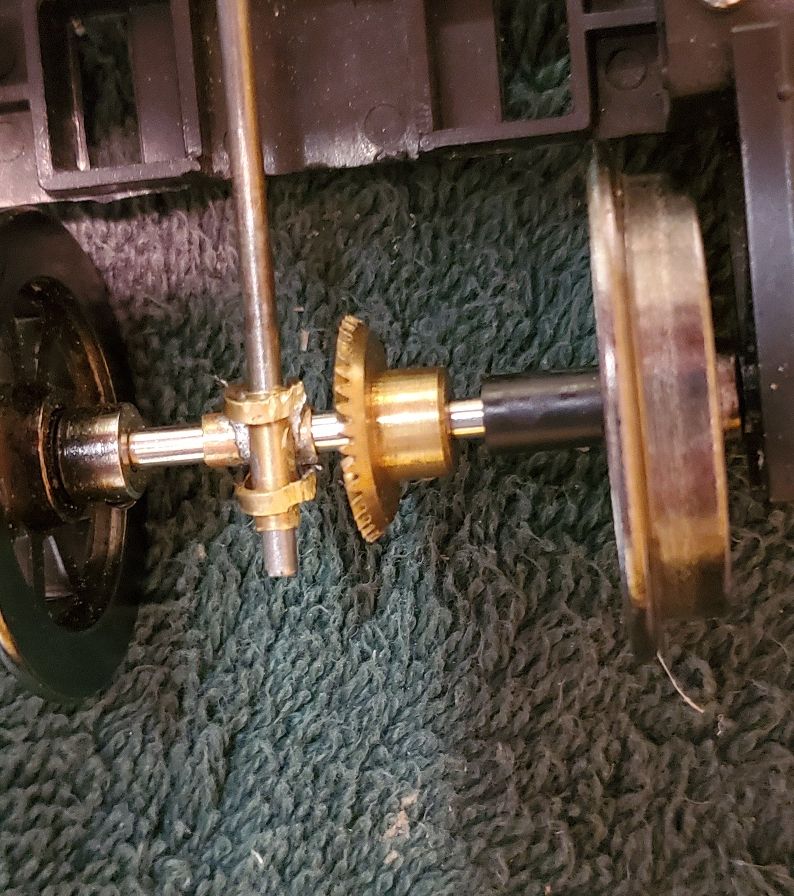

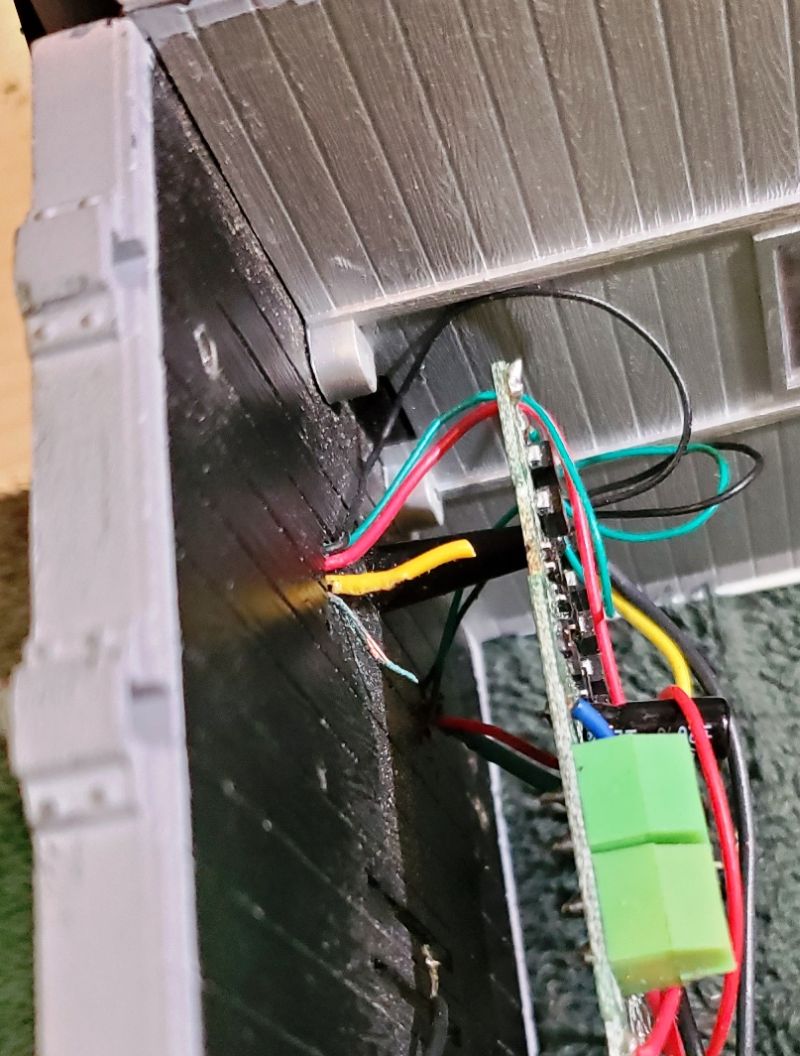

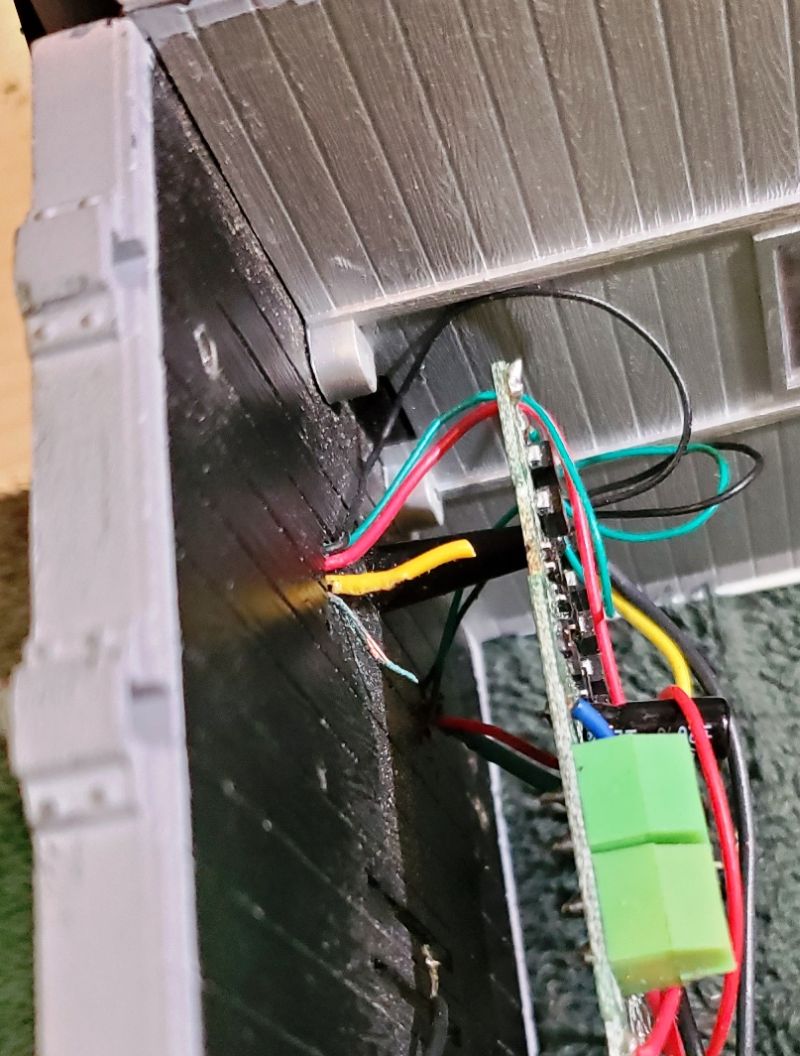

Having fixed the front truck, I separated the B’mann truck half from the boxcar half and tested it with an old 12V power pack. The rear pickups came with it so it was easy to apply power there, and the motor turned nicely. No joy from the front though. I printed my wiring diagram (from the B’mann parts website) and poked around. There are supposed to be 2 yellow wires from the front truck to the PCB in the bed - mine were both in terrible condition. On the first pic you can see the corroded (!) wire on the right, out of the split insulation. [Curious - none of the other wires were bad.]

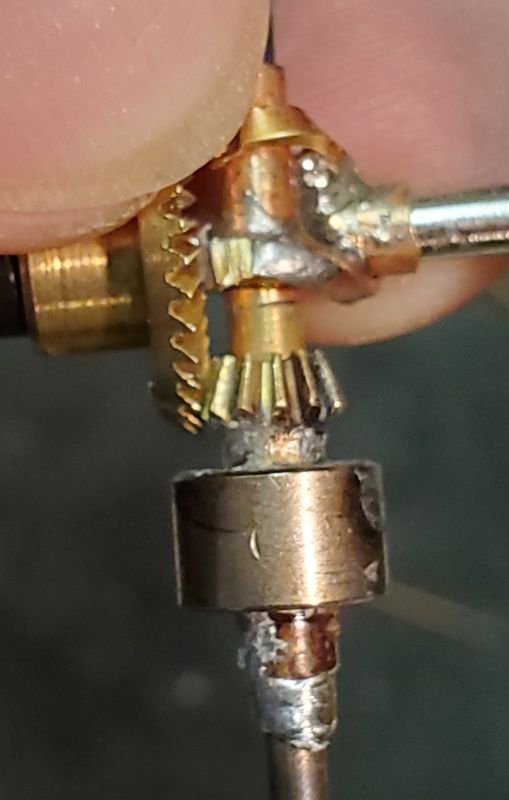

The other side had corroded deep into the underside frame:

Well, it was a pain to clean the corroded wires and solder them, but now we have continuity and the motor runs when powered from the front or the back.