Hi guys,

I’m brand new to your forum and I’d thought I’d say hello by adding to this thread. I have a lot of experience with this loco. It is one of my favourites but I did come close to throwing it in the pond a few times too!. I have taken these trucks apart so many times I can’t remember and I finally did the “permanent” fix to them summer before last. The loco has been working great since.

Here is what I noticed…those pick up springs are a nightmare! - so are the ones that pass through the truck into the cab. If the loco gets stuck or has an overload for even a split second, they get cherry red and lose their “springyness” - they make no contact after that.(can’t tell you how many times I disassembled the trucks to re-stretch those springs - only to have it happen again.).

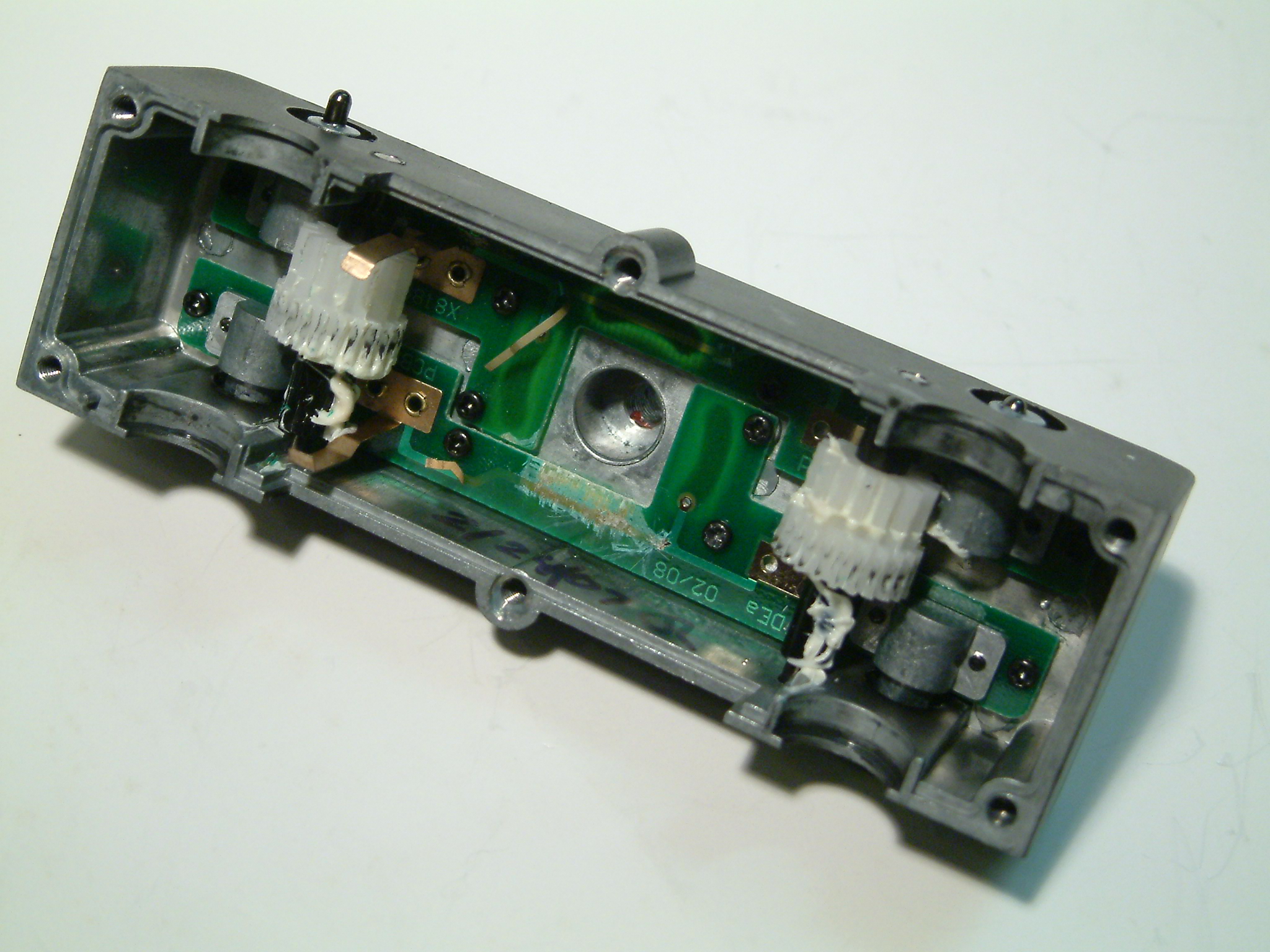

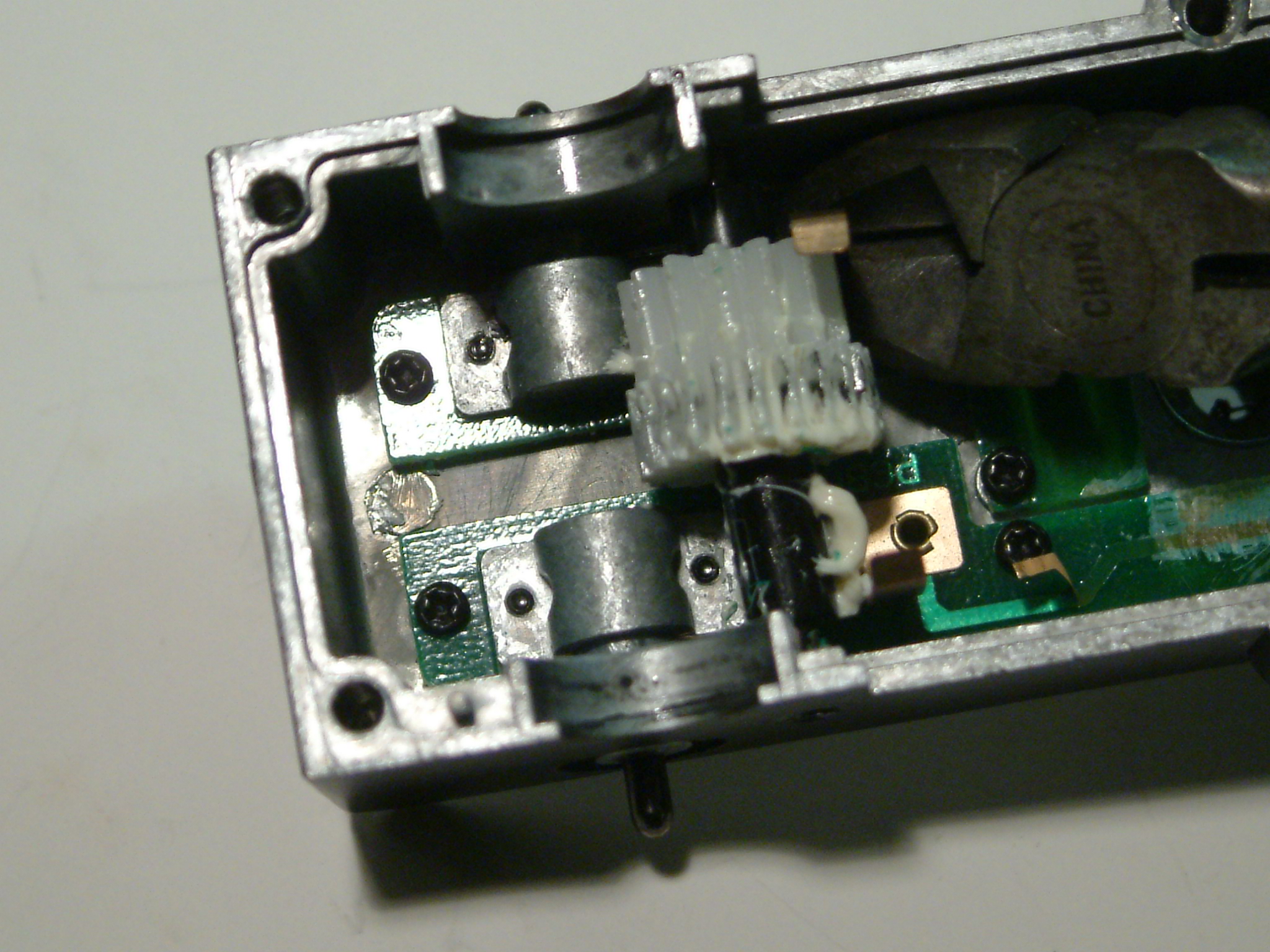

To get the little cast "spring holders out - you have to “punch out” the axles and gears - be carefull and take pictures.

Next - remove the circuit boards - the spring holders are screwed on from the bottom side. (makes sense huh?)

Here is what I did - I used a small dremell die grinder and opened up those small cast spring holders to accept the LGB spring loaded carbon brushes. It took some time and a little finesse but it is completely doable. - they will fit with enough grinding. In the end, they will look like very small “u” holders used to clamp copper pipe onto a wall - if that makes sense. You may have to use some shims to hold in the new brushes. I used small, thin pieces of gasket cardboard.

I then just soldered a wire between each pair of brushes (each side) and then sent another wire from each side, up out of the truck to the cab. I Bypassed the small circuit boards completely. Had to open up some holes in the cab to do this.

The Loco has performed perfectly since!

Hope this helps - I would include pics but I don’t want to take mine apart again.

I didn’t have a problem doing this because mine was old and out of warranty anyway. Not sure of your situation.

Cheers

Mike

Fonthil,l ON

EDIT:If I have time tonight, I will pop the bottom of one of my trucks and take some pics - I’m new to the forum so I’m not sure how to add photos yet but I’ll try after work