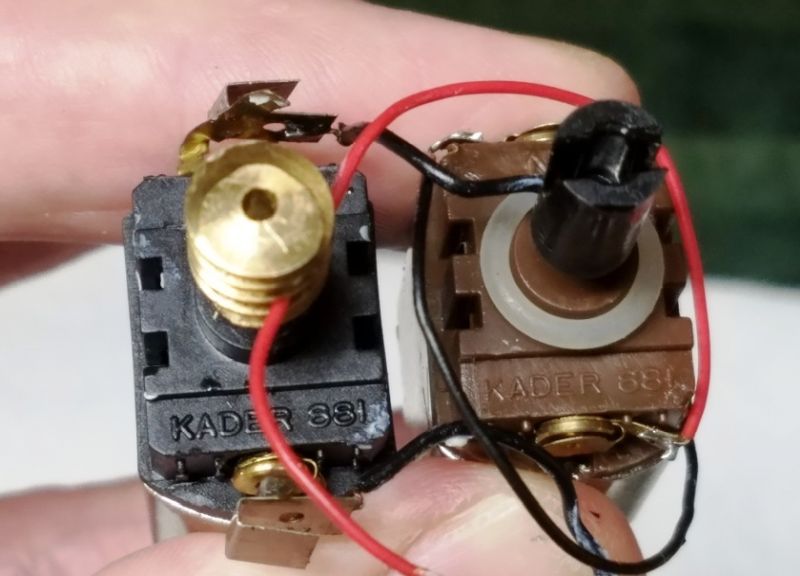

Last year I fixed the motor in a Bachmann streetcar [ https://www.largescalecentral.com/forums/topic/28736/re-motoring-a-bachmann-4-wheel-trolley ] and this year I volunteered to fix a similar motor in a Railtruck. Bachmann uses this “881” motor in all kinds of trains, including HO diesels, the streetcar, railtruck, and who knows what else. The motor has “KADER 881” molded in the end plastic cap.

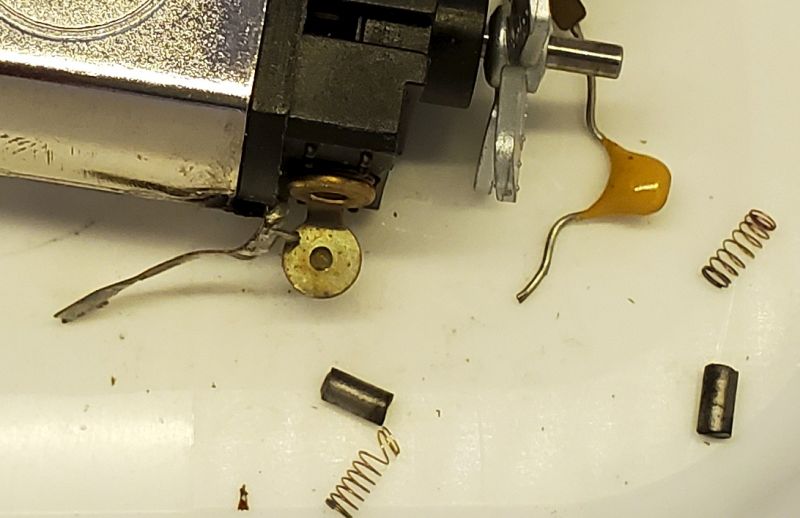

My multimeter showed no signs of a connection across the motor brushes, so out they came. The butter tub is needed to catch them - they are very, very small.

Here’s a close-up of the brush holder. You can see the hole for the brush, and that little round cap with the dimple is just folded over to hold it in. (I believe most motors are mounted in a location where this brush cap is restrained from opening.)

The trolley had a broken brush - these seemed OK. I did take the end cap off just to have a look inside. It has 4 little tabs bent down into slots on the end cap near the brush holders - lever them up with a small screwdriver.

While I had the cap off, I tested the windings by touching each adjacent pair of commutator pieces with a meter set to read ohms. [The commutator is what the brushes rub on, and it conveys power to the wire on the poles of the motor. All windings should read the same.]

This is sort-of how you do it. It’s a lot easier if you aren’t trying to hold the camera at the same time. While you are at it, clean the commutator with some emery as it will probably be black with brush residue.

OK. All the readings were consistent, so I put the end cap back on and bent down the tabs. (Tapped them with a small drift - square punch.) I then clamped the motor so it would stay with the brush holder up, and I dropped a brush into the hole. Then I gently, very gently, extended the spring and dropped it on top of the brush. If the spring did not end up just proud of the surface, I tipped it all back into the tub and tried again.

When I had the brush visible in the holder, I folded the tab back on top of it to keep it in place. Then flipped the motor over and repeated the process on the other side.

And that was it. I applied power and the motor ran. My theory is that, after 10 years of hot-and-cold operation in the motor, and with the brushes slowly wearing down, the springs squash just enough to stop pushing on the brushes. Next time I will just take the springs out, extend them, put them back and test. Might only take 5 minutes, instead of 15!

It’s a shame Bachmann doesn’t sell spare brushes and springs. A new spare motor costs $19.80, though I have found HO locos on eBay for parts with the same motor for $10. [ I do not know if the 12V HO motor is identical to the “Large Scale” motors, which can operate on 12-18V, so if it melts don’t blame me. One day I wil try one and find out. ]