Ok, Since Devon asked for it, I will start my thread on my kit-bashing of a Tyco 10 wheeler into the Hooterville Cannonball.

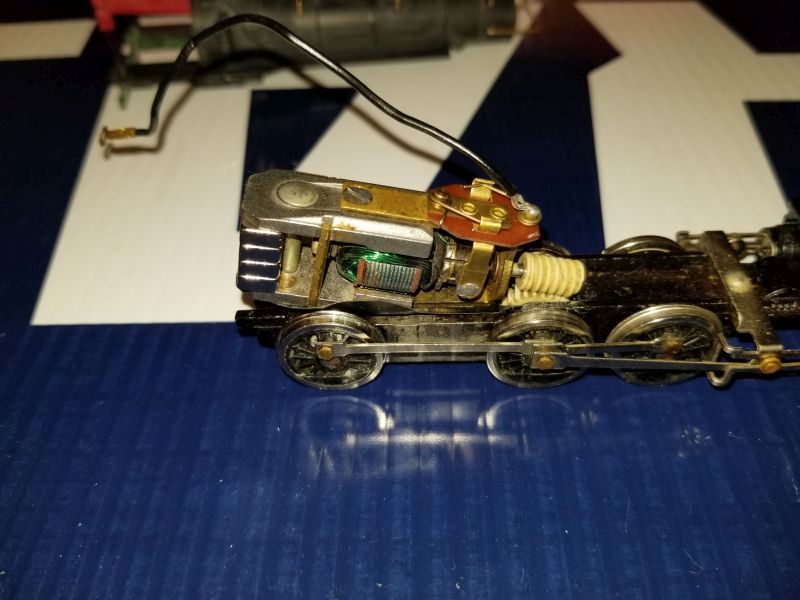

As with all my Tyco rebuilds so far, I start with replacing the motor magnet with super magnets from Micro Mark. These magnets are much stronger then the original magnet, and cut the current draw of the motor nearly in half. I also adjust the bearing plates to remove most of the lash from the motor, and lube the motor bearings with a drop of oil. Then I power up the motor and run it both directions for a while till it settles down and will run at a nice slow speed. Most times these motors haven’t turned for a few decades, so they need a little time to run the stiffness out of them.

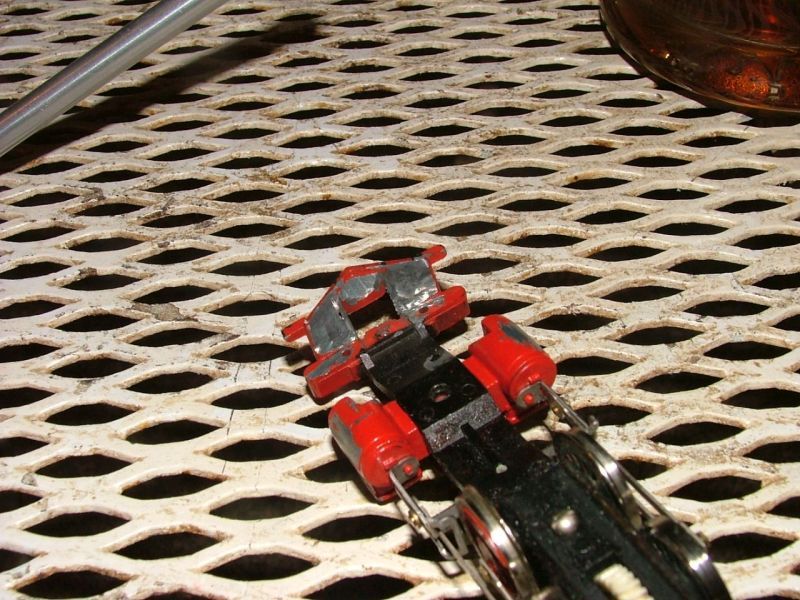

Then I replace the rear driver with one that does not have the traction tyre.

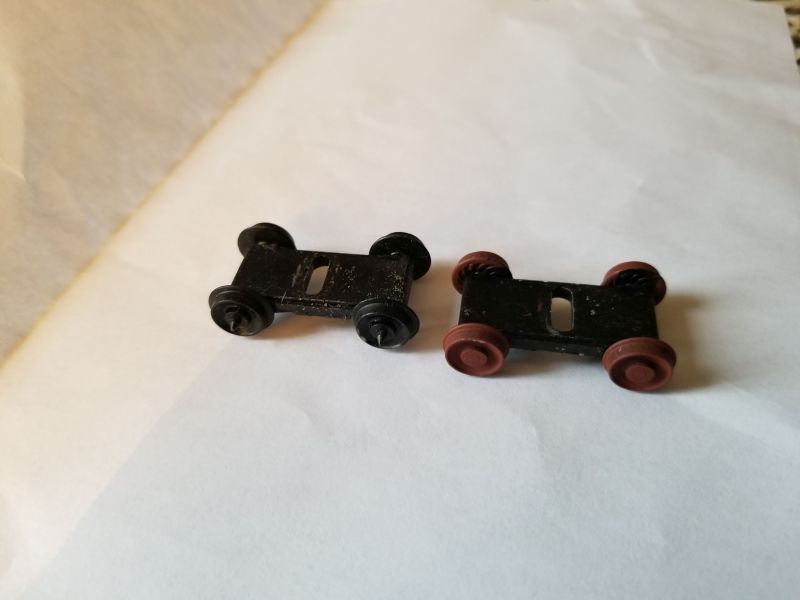

The traction tyre stands proud of the tread, almost as far as the flange. This can cause derailments. To get the needed drivers, I purchased 2 “for parts” (trashed) Tyco Mikados. The Mikado uses the same drivers as the 10 wheelers, but none of the Mikado’s drivers have a traction tyre. Only the first and last driver of the Mikado are flanged, but for the price of a junked locomotive, I can fix 2 10 wheelers.

To isolate the motor from the frame, I put a layer of electrical tape on the bottom of the motor, and reattach the motor with a KaDee, Nylon, 2-56 screw, trimmed a bit for length.