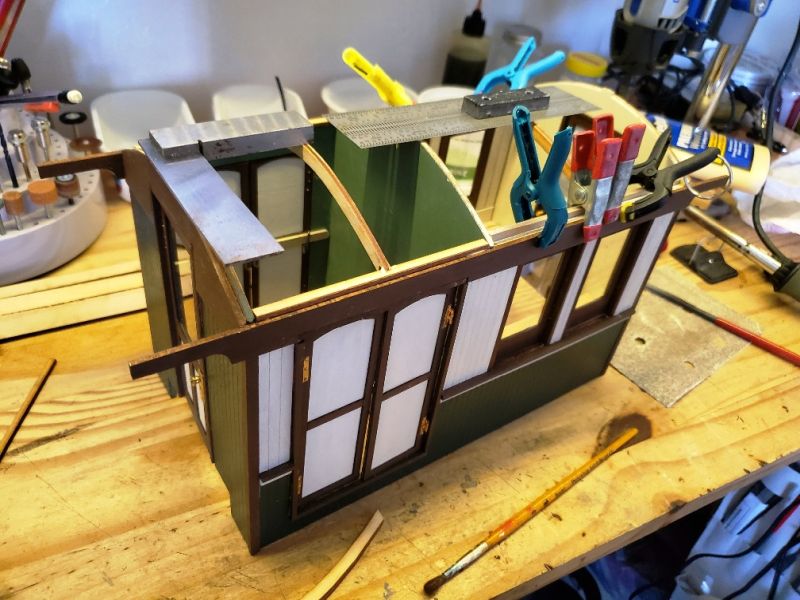

I’m working on my stash of kits and trying to get this 7/8ths scale combine finished. It’s slow work, as it was originally a Twin Mountain kit by Carl Malone that Ozark took over, and the instructions are, shall we say, deficient. The parts added by Ozark aren’t wonderful. (I got an early one, so maybe they are now improved.)

My current problem is making the feight doors stay closed in a reasonably prototypical fashion. I’ll glue them if I have to, but I would rather not. Here’s the freight door end, and you can just see the crossbar holding the freight doors shut.

Unfortunately the kit didn’t include any hardware for the door other than hinges. I squashed some brass tube and bent it into a piece that would hold the crossbar.

The problem is that the bent brass pieces aren’t well glued to the doors as they aren’t big enough. This morning when I was sanding the roof I inadvertantly grabbed it by the doors and half the brass bits dropped off and are lost. I can make some more, but I wondered if anyone had any thoughts on an alternative way to keep the doors shut and yet be able to open them if I wanted. (P.S. I don’t have a machine ship - a Dremel in a stand is the extent of the power tools on my 4’ long bench!)