This afternoon I fixed a Bachmann GE 45 ton Diesel which refused to operate with both trucks at once. It was new, but those silly plungers are just a pain. If any 1 of the 8 isn’t contacting perfrectly then it doesn’t run - one truck tries to pull the other. (I hear the Heisler is the same, and I know the front truck on the Railtruck is also plunger driver.)

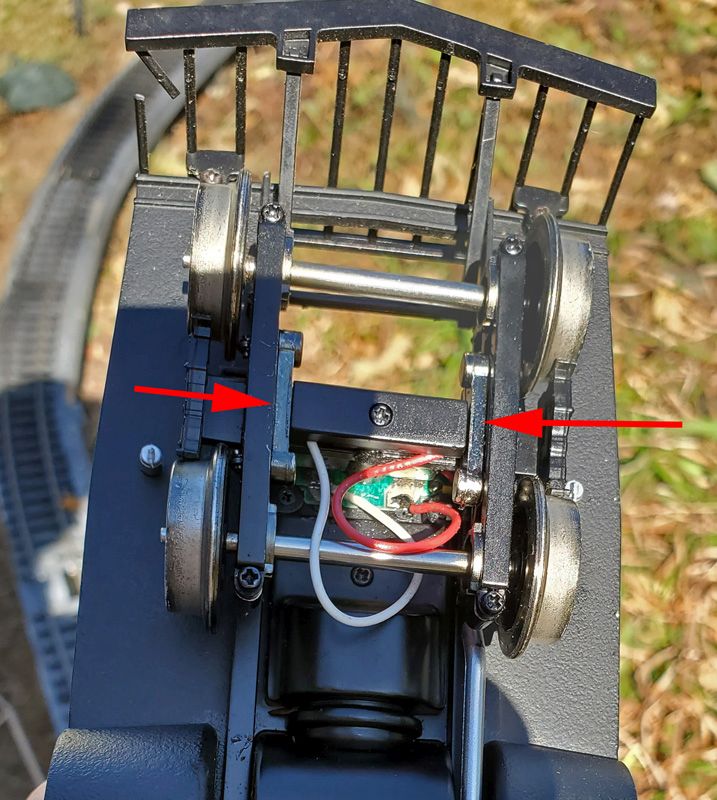

Jerry and I took it apart per Kevin’s instructions, and I soldered wires from the pads on the truck to the contacts on the loco, as you can see. I kept the position the same - I even got the red-black right on one truck.

Oh yes, the instructions from Mr K:

The plungers are crap. You’ll want to hard-wire the truck to the loco. There’s room to put a small 4-pin plug at the top of the truck if you want to make things detachable.

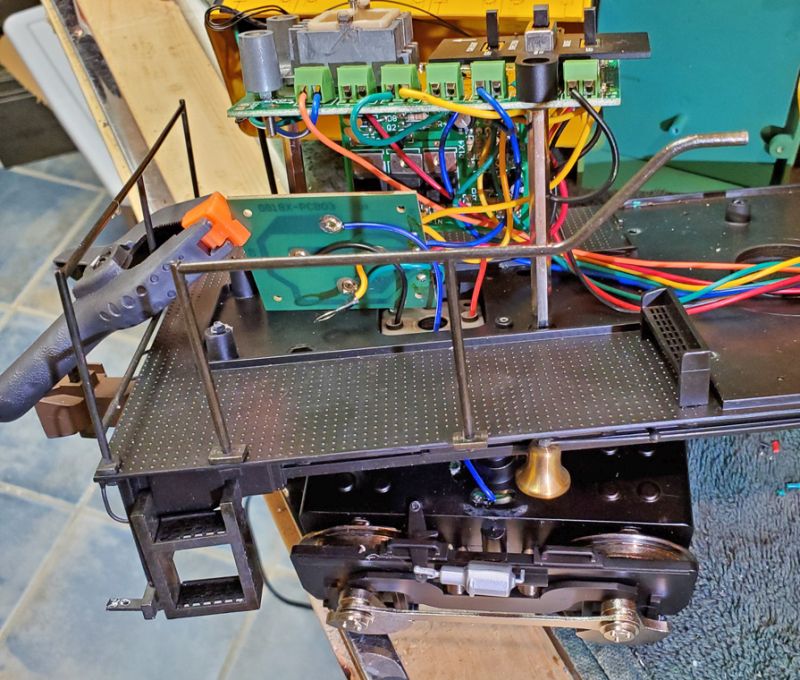

To get to the trucks, pull the body off. You’ll need to release the fuel tank first. This exposes the 6 screws which hold the cab in place. There are then 2 crews at the ends of the two hoods. You’ll find two elevated PC boards under each of the hoods, then on the floor, a smaller PC board held to the floor with screws. This is what carries power from the trucks and to the motor. Keep track of those wires. Removing this board exposes the screw which holds the trucks to the chassis. Remove that screw and the trucks drop out.

On the truck, you’ll see 4 open contact areas on the PC board. I’d have to check to remember which two go to the motor and which two to the track, but they’re opposite each other—north/south for one, east/west for the other. You should be able to solder to those pads without too much trouble, though you’ll need a thin tip on your soldering iron to reach through the openings.

In fact there was little need to keep track, as on this loco the boards were marked: motor-1,motor-2, con1, con2. I just threaded new wires through the plunger holes and reconnected them to the board where the appropriate plunger used to be. I left 1" or so of wire under the floor so the truck could swivel.