I purchased what was listed as a “Like New” Aristo wide switch form Bart “Mad Dog” Burger on Facebook. When it arrived it was far from new. Rail was somewhat corroded and loaded with spider webs. The switch machine was completely broken as was the throw-bar. “Mad Dog” replied immediately to my email saying he would send new parts, but to date still has not and went silent for over a month until he went to post new items on the Facebook swap group and noticed my bad review of him. He responded on FB that “Like New” is not New. OK, fine; but where are the parts you promised?

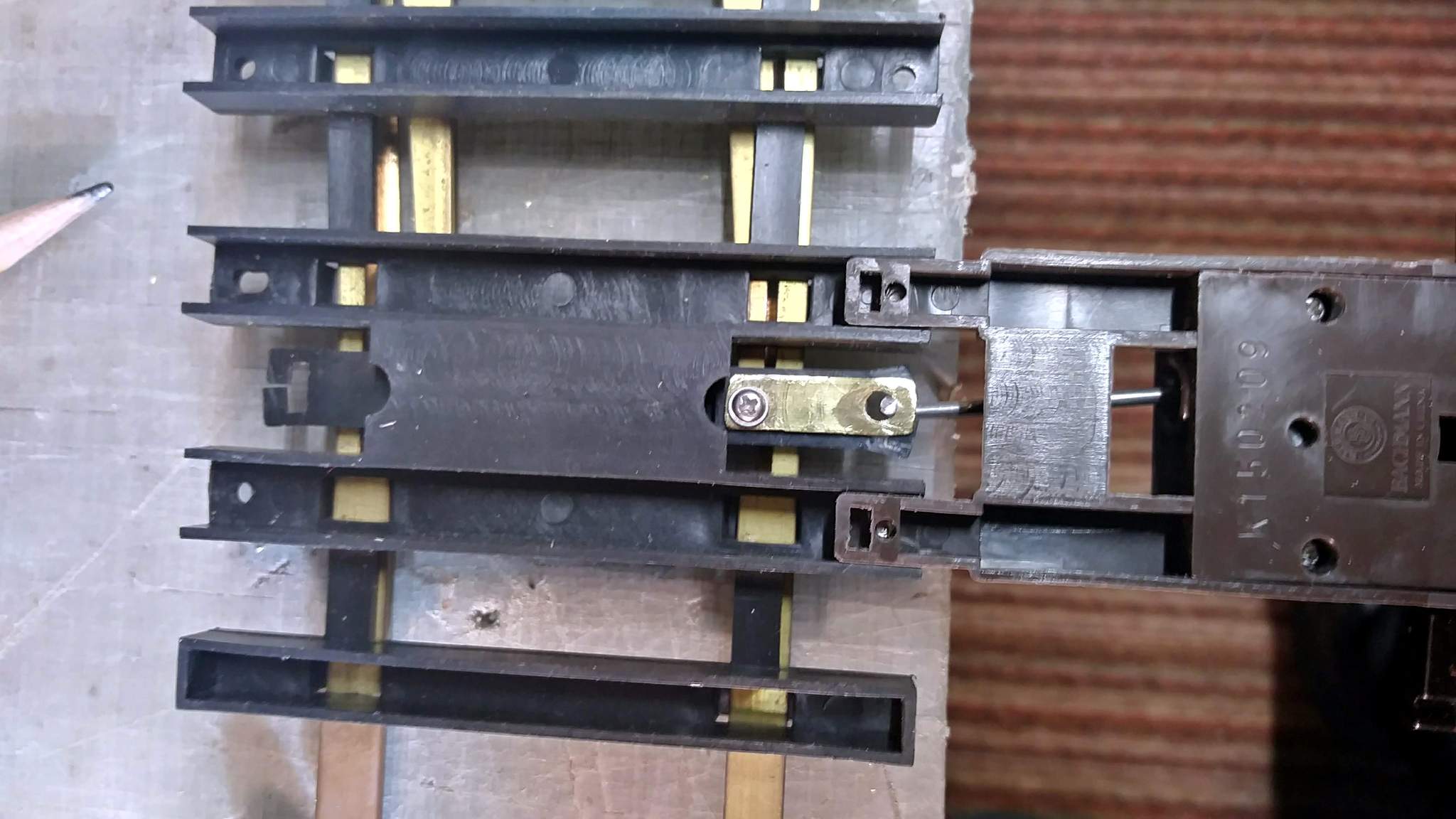

I need to install the switch today, so I gave up on the Dog and fashioned my own quick fix. A Bachmann throw and a small piece of brass did the trick…