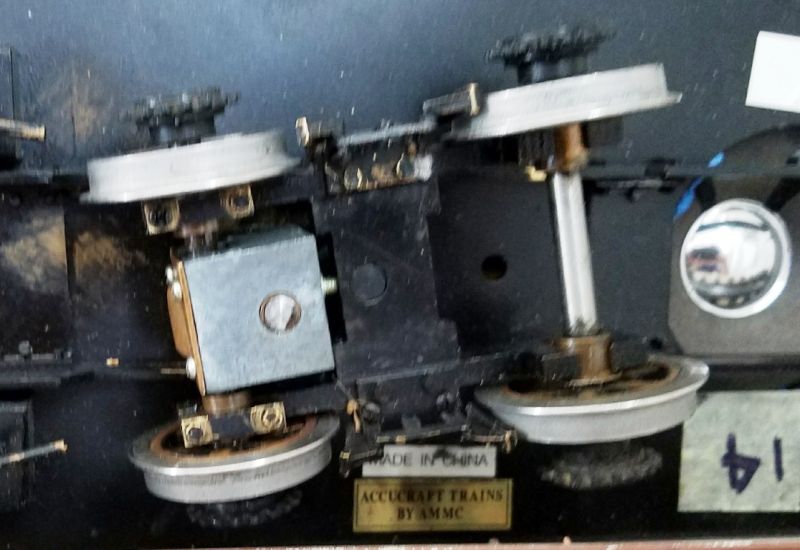

My pal has an Accucraft Goose #2, which chewed up its gears. He bought a replacement from NWSL which was a good fit, but after running it he discovered the gearbox driveshaft, which is vertical in the gearbox, had slid down and was catching on his track. (See first photo. The driveshaft is only a loose fit in the motor, so the shaft was also about to drop out of contact with the motor.)

I figured the gear was slipping slightly, and allowing gravity to let the shaft move lower as the motor/car ran. So I offered to groove the shaft and put some loctite or similar on it.

Disassembly is easy - you can see the well-worn bolts that hold the axle and gearbox in the truck frame. Here’s the parts, after popping off the gearbox cover.

For some strange reason, the hornblocks (square bearings next to the gear) have little springs that push the gears away from each other. I’d have designed it to do the opposite.

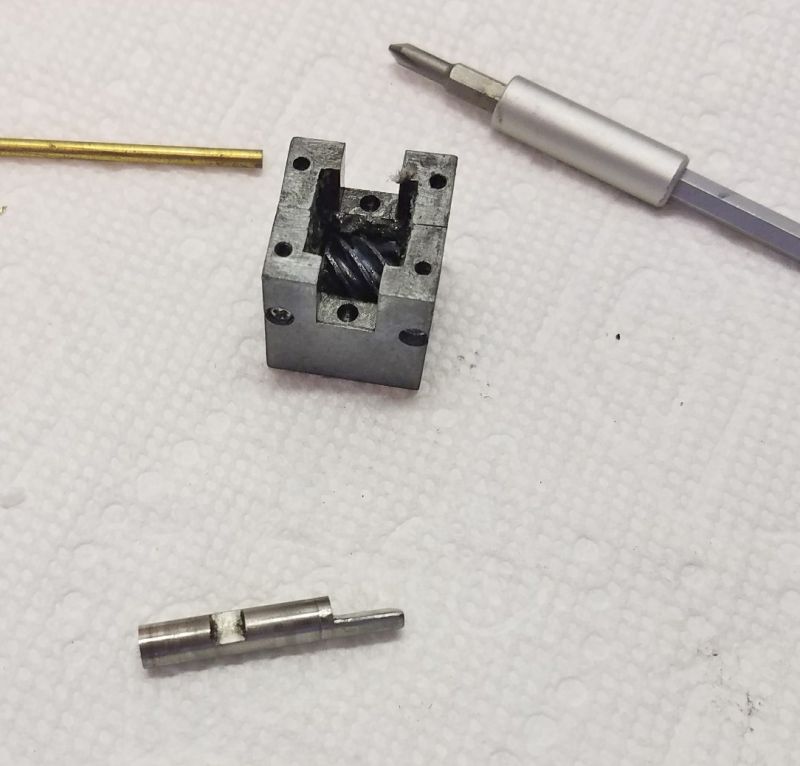

Anyway, here’s the driveshaft and gearbox casing. I was surprised to find it already has a flat on it - though there is no pin or screw in the nylon gear to take advantage of it. The end of the shaft is also half cut away, as it fits into a similar shaft on the motor above. There’s a tube holding them loosely together.

So I grooved the inside of the nylon gear with a small saw and the shaft with a Dremel cut-off disk. I also split the gearbox housing to clean it.

As the bearings came out, it was a simple matter to clean everything, slop lots of blue Loctite on the shaft, and tap the gear back on. The bearing served as a depth guide.

After reassembly (with more Loctite on the screws, and a little oil,) I found the wheels would slide rather than turn a (slipping) gear against the motor. We should be testing it in a couple of days, so fingers crossed.