Two observations, gleaned from the posted pictures:

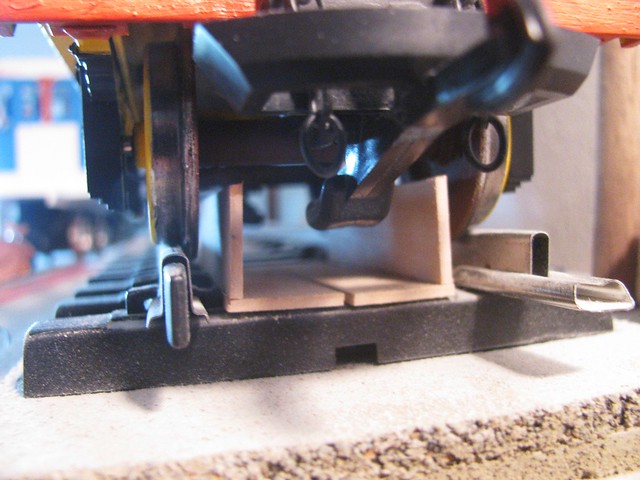

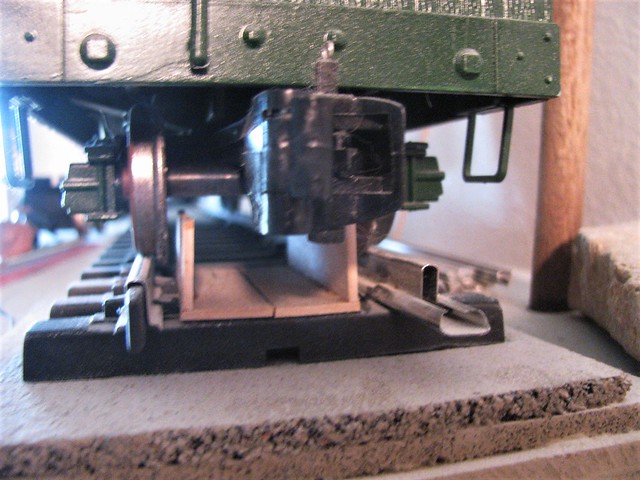

In one of the pictures, the car (Wheels) are sitting on a piece of B’mann track. Note that one wheel is raised slightly off the rail. This could indicate that the wheelset is out of gauge, or the track is out of gauge. This in itself should be checked out and corrected, as it can effect coupler height, and the tracking of the car for good derailment free operation.

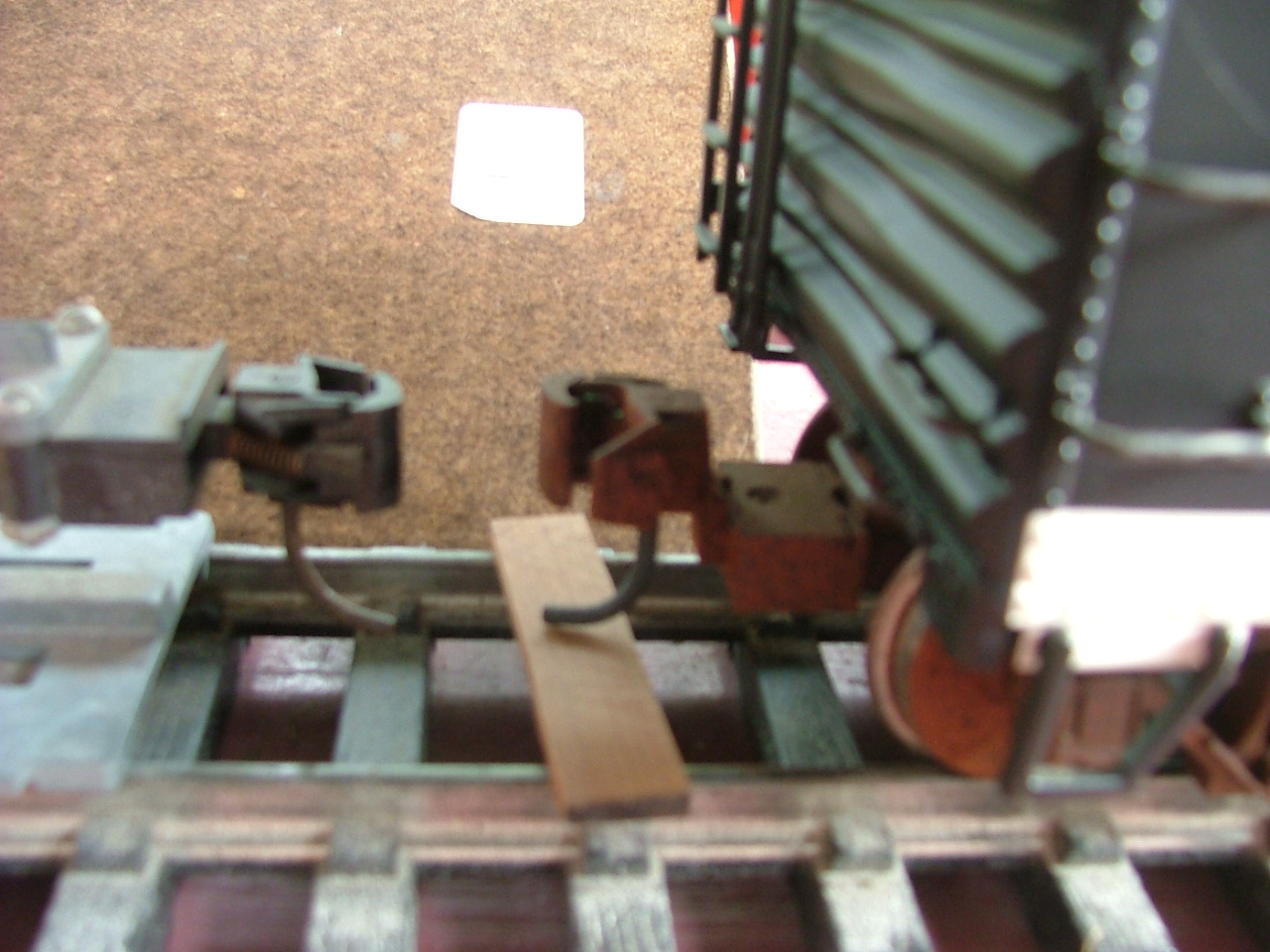

The second observation is taken from the picture of the Kadee coupler mounted on the box car. That offset coupler looks like hell, and is so unprototypical that I cringe whenever I see it. But… so many people seem to use that method of mounting couplers…surely some must care about how their models look…or are they a new breed of modellers who have no idea of prototype practises, or just don’t care.

I don’t mean to in any way insult anyone, but…egads, lads; you can do so much better, and have more pride in doing things with some prototype knowledge, easily learned from such web pages as LSC, and all its members.

My guess is that the person owning the box car, either has tight radius curves and can’t use body mount couplers, or is afraid to learn how to body mount them properly…or is worried about ruining the value of the car for future sale to some collector.

These are just observations by me, and are admittingly passed on with the knowledge that everyone has the freedom to do things their way, and if I don’t like it, I can piss off…!!

Smile…are we having fun yet !!..??

Fred Mills