Trestle Bridge help

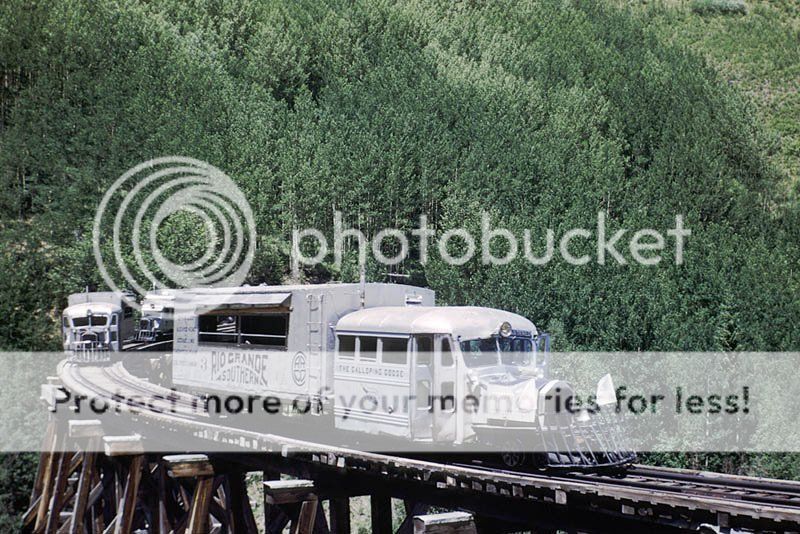

The first picture looks a lot less precarious than the second, and also looks a lot more realistic.

I did my trestle like the bottom picture. Narrow gauge railroads seldom added more to their structures then was needed to get the job done.

What are your temperature shifts like?

When it gets hot, I’ve seen my track move a half an inch (12mm) or more, to the outside of the curve. I built my curved trestle with 3 stringers to allow for the shift and to keep the rails supported.

Korm is indoors and can be more prototypical, I made my stringers taller than the safety timbers on the deck tie ends, so my track could clear them, on it’s walk about.

My temps range from freezing to heat stroke …

John Caughey said:

What are your temperature shifts like?

When it gets hot, I’ve seen my track move a half an inch (12mm) or more, to the outside of the curve. I built my curved trestle with 3 stringers to allow for the shift and to keep the rails supported.

Korm is indoors and can be more prototypical, I made my stringers taller than the safety timbers on the deck tie ends, so my track could clear them, on it’s walk about.

My temps range from freezing to heat stroke …

Usual temperature range is from high 88F in summer to 60F in winter with sometimes a peak of 92F and extreme low of 45F but these are not the norm and only happen for a couple of day.

Hopefully your lateral movement will be less. My straightaways push on the corners for expansion relief, that’s where the give is. Allow for lateral movement.

I did it the toy train way and laid the track on the trestle. Where I removed the plastic ties, I should have only spiked to floating wood ties … between secured ones. Live and learn…

John Caughey said:

Hopefully your lateral movement will be less. My straightaways push on the corners for expansion relief, that’s where the give is. Allow for lateral movement.

I did it the toy train way and laid the track on the trestle. Where I removed the plastic ties, I should have only spiked to floating wood ties … between secured ones. Live and learn…

There is so much slop between my track and the sleepers that expansion can happen plus I use slide on joiners with gaps between rail ends where I can.

The gap makes a nice click clack sound when metal rails pass over them just like the old trains did.

Unfortunately with the slide on connectors, they rarely go back where they were on the path of least resistance. It’s possible that all the gaps migrate to one section.

I torque my track together with the screws through the joiners and make it one solid unit and it still needs an occasional nudge back into alignment. Your mileage may vary…

You guys think you have temperature variation…try a range from -30C to +40C…and I nail my track to a 2x PT roadbed, of course allowing expansion at all rail joints. I do have the freedom, with Battery Power/dead rail, to not have the worry of good electrical contact at rail joints…but I’m NOT trying to promote an “Electrical war” here.

Fred Mills

My Gawd Fred, your track must shrink down to nothing!

I’m more concerned with shrinkage after expansion.

My track is a single unit, but it doesn’t always go back to it’s center line. Then the 0-5-0 big hook reaches in and corrects the misalignment.

Does live rail shrink differently from dead?

Slide on connectors.

In Vermont almost all the members of the Vermont Garden Railway Society switch to either Hillmann or Split Jaw or other rail clamps.

Why?

Most of our tracks are outdoors and are left there year round.

The temperature can swing from near 95F in Summer to -20 or below:-( in Winter.

In winter the track shrinks a little bit away from the slide on connector-over a few years grit from the ballast sneaks in and causes electrical continuity problems.

Clamps designed for over the slide on connector still allow the freeze shrink:-(

Most joints are replaced by rail clamps, particularly at switches.

More added cost, but SO easy on the hands and knees and joints

I would actually be more concerned about the joist on the far right not set on the bent as opposed to the rest of the suggestions currently given so far !

Since there were before pictures, I suspect this is more cosmetic as opposed to structural

Fred Mills. said:

…and I nail my track to a 2x PT roadbed, of course allowing expansion at all rail joints. …

i’m with Fred on this. my track consistts mostly of 1 foot sections and i nail every section down on one end. with spaces, that average 1 to 2mm.

yes, my layout is “in doors” but the room is a better lean-to shack between two buildings, lacking heating and sufficient cooling. temperatures vary between about 40 and about 95 F. (5 to 37 C.)

but it is at least in the shade! so, there is some expansion. and, even without expensive clamps, the track does not “wander”, thanks to the nails.

The sun on the rails makes a big difference, that is for sure, makes them much hotter than ambient.

Rooster ’ said:

I would actually be more concerned about the joist on the far right not set on the bent as opposed to the rest of the suggestions currently given so far !

Rooster

That joist is glued and nailed to the bent the nail goes in at an angle, it is also glued to the cross brace and the other joist, it also comes into the area at an angle as opposed to the others that are in a straighter line.

I have decided to add a walkway across the back, after many suggestions from numerous forum members both on here and another in the UK, so extra strength will come from there.

I am fairly confident that this thing is not going anywhere in a big hurry once it is finished.

Greg Elmassian said:

Since there were before pictures, I suspect this is more cosmetic as opposed to structural

Correct Greg,

The joists are mostly cosmetic the strength comes from the bent being screwed to a timber between 2 side rails and the timber supporting the rail.