Hi guys,

I have finally begun my D&RGW caboose #01157 project. I decided to do this build a couple of years ago after seeing this pic of said caboose in Leadville, Colorado:

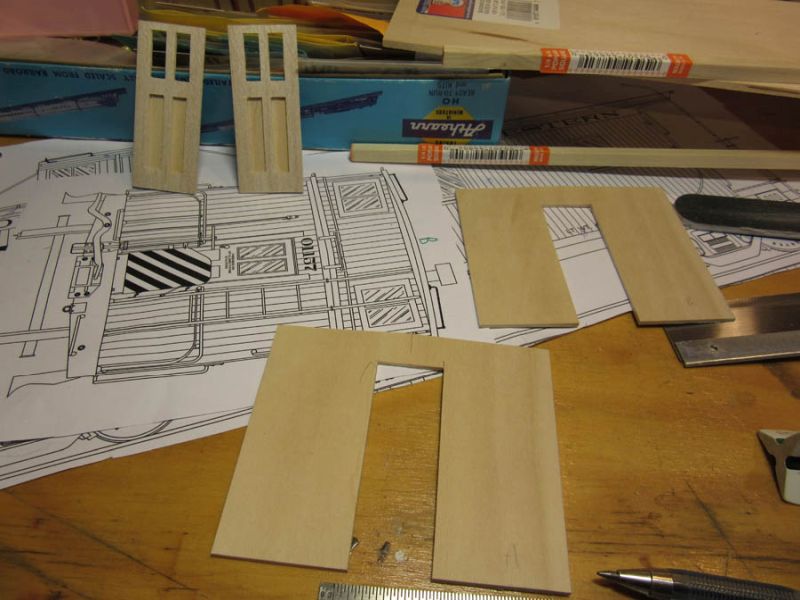

I found that there were two surviving examples of this class of Grande caboose. One, #01152, was located relatively nearby in Lake City. I found out who owned it and got permission for a visit in the spring of 2018 and took a bunch of measurements and photographs. I then developed plans in AutoCAD- said plan is attached. The Lake City caboose looks like this:

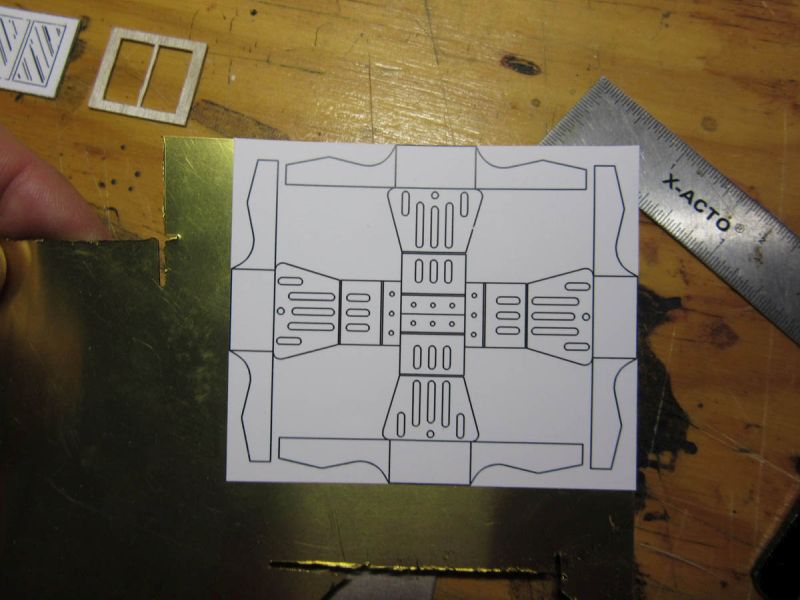

I started buying parts and raw materials. In November of last year I made a half-hearted start. Along the way I had purchased a USA Trains center cupola caboose off of eBay. I replaced its trucks with standard USAT freight trucks and re-sold the caboose. I soldered together a frame from 1/4" square brass tube and added some truck supports stolen from piece of retired rolling stock and then added the USAT caboose trucks:

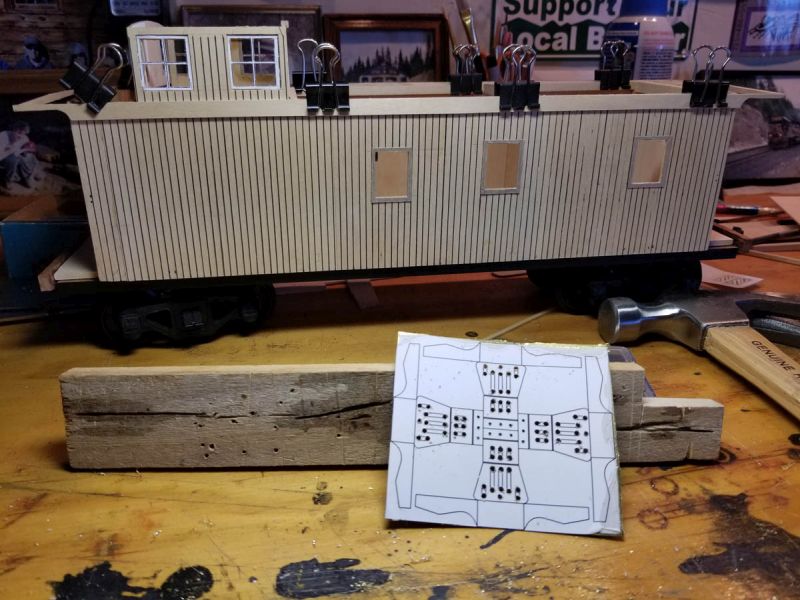

Over the weekend I began in earnest, for now at least. ![]() I cut walls from 1/16" basswood and framed them with 1/4" square basswood. I don’t DO interiors, so I’m not worried about a sloppy inside:

I cut walls from 1/16" basswood and framed them with 1/4" square basswood. I don’t DO interiors, so I’m not worried about a sloppy inside:

Tonight I taped the whole mess together to make sure everything fit the way I hoped:

Next step will be to scribe the walls to simulate siding.

Cheers,

Matt