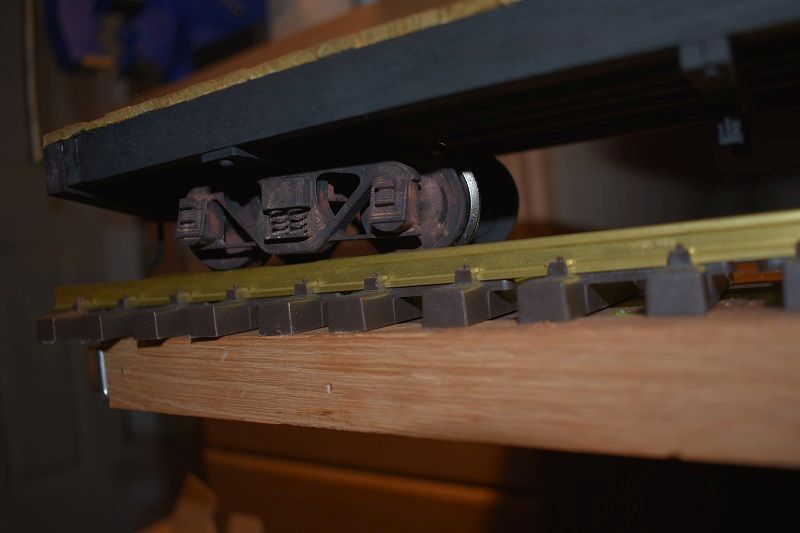

Next car to join the Brown Dog Timber & Lumber Company roster is a tie and rail car. This is the 3rd installment in our work train series. The first two were the work caboose (Build Log) and a flatcar (Build Log). This build started with the construction of a flatcar more or less identical to the one we just completed. The tie deck was then added. The photos below show the tie deck temporarily mounted just to get a feel of the overall look. I still need to add 2 more posts on the far side and the ends to the tie deck. Once that is done, I’ll remove the deck and everything will get a coat of paint and weathering. Then we will add the underside details and trucks.

Thanks for following along.