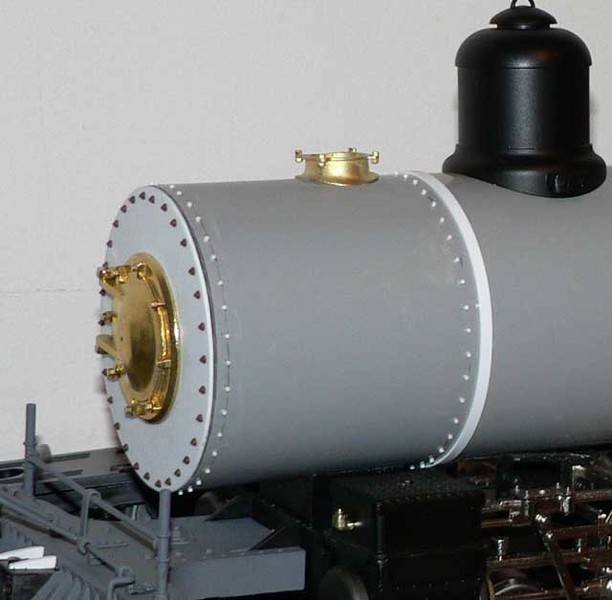

I’ve tried various ways to simulate rivets in the past. When I originally built my 1:20 ten-wheeler, I sliced styrene rods to make very tiny cylinders and glued these in place on the side of smoke box. The front is done with commercial castings.

Needless to say, that was rather tedious for both methods. I have also used a pounce wheel. It was far less tedious, but the rivets are not crisp. Not only that, but you’re stuck with the spacing on the wheel.

Next, I tried texture paint. It’s not bad looking, but the rivets are rather all different shapes and sizes.

When it came time for my 1:20 Mikado project, I wanted something that looked very professional. None of the previous methods would work for this project.

When my Ten Wheeler bit the dust, that gave me extra incentive, as I would make a new tender and cab for it as well. My solution was to make an order from Micro-Mark. I debated long and hard for this as it is not inexpensive.

Not only that, it’s not just one thing. It starts with Press-It…A Precision Arbor Press. Add to that Emboss-It Model Rivet Simulator. This is a table that fits on the press and moves left/right in .001 increments. Finally, I got the Rivet Embossing Set which gives you .018, .026, .033, .041, and .050 inch rivet diameter punches and dies. This allows you to punch the different size rivets when they are put in the press.

In operation, this works well. I tape the styrene (in this case .020" thick) to the base of the table. I use a ruler and square to make sure that it is oriented correctly

For a long sheet, like this tender side above, I made several passes. This means re-taping the sheet and setting it up again. I used a previous rivet to align it when continuing a row. It’s very helpful to mark lines on the side to be punched; remembering that this is the BACK side. I used a Sharpie at first, but found that the line was too thick to give me accurate placement. Later, I used my .5mm mechanical pencils to draw a finer line.

I’m pleased with the results.

In the above picture, the bottom row of rivets is spaced two complete turns of the know. Each turn moves the table .050", so the distance between these rivets is .100". The middle rows of rivets are 4 turns apart, or .200". For my cab, I used the next smaller rivet size (.033"), and a spacing of 3 turns.

In the future, I’d like to do rivets for pieces like the boxcar door trim, but there’s no obvious easy way to move a strip that’s only .100 wide from left to right using the table. I’ll have to devise some sort of carrier to allow me space the rivets evenly.