Some of you may know that I’ve used Shapeways a lot over the last 5 or 6 years, especially for model-making for my full time job. I’ve generally used their (cheapest) SLS nylon, because it’s… cheap. Not fantastic detail, but very rugged, and the build volumes are large. I don’t use FDM much, because my machine no workie, and the SLS doesn’t have the layered effect.

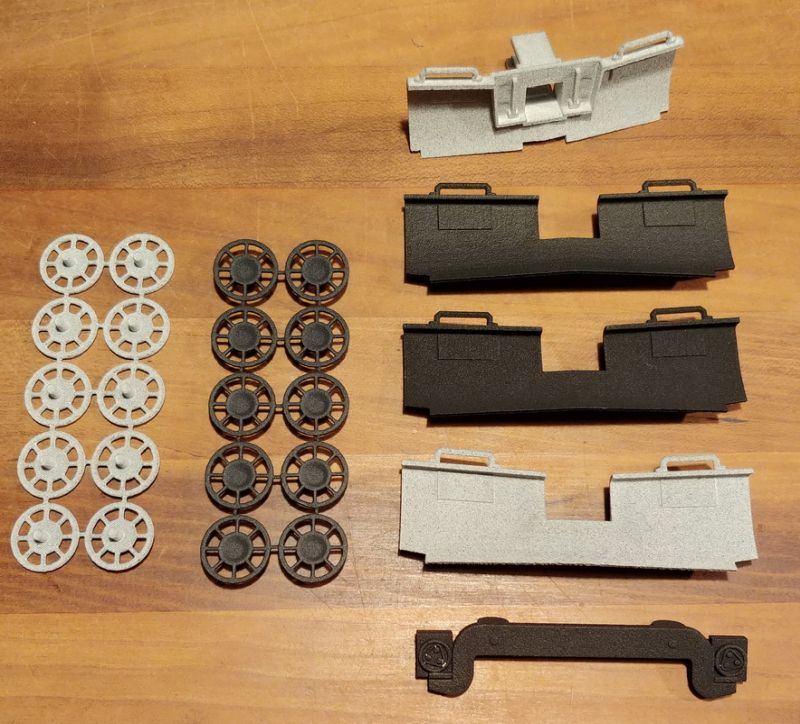

Recently (for a couple years?) they’ve offered “engineering plastic,” which has finer detail and better strength. And it can be had in black material: not just dyed white, but black (or gray) all the way through. This is important when you sprue parts together and then need to cut the sprues off.

But, the Shapeways’ “engineering plastic” ain’t cheap: 2 to 3 times the SLS nylon (they now call it “versatile plastic”) cost.

Their “engineering plastic” is the product of Hewlett-Packard’s Multi-Jet Fusion printer. Still nylon, but a better process / material type. So, if you find another place that prints with that, you should get the same outcome. 3DHubs started using it, but their prices quickly got even higher than Shapeways. Xometry also does HPMJ, but they’re even more. The good thing about 3dHubs and Xometry is volume pricing, which SW doesn’t have. 3DH & Xom are going after production markets, not just one-off’s.

OK, I’m finally getting to the point. I don’t need volume pricing for now, just good HPMJ product (in black; not everyone does that) for my one-off projects. I finally found a place to try out, Jawstec. Here’s the comparison for 2 different parts, using the same process / material / models.

Shapeways: Part 1: $151; Part 2: $55

Jawstec: Part 1: $58; Part 2: $18

About 1/3 the cost! So I placed my order with JT, and will post on the quality when I receive the parts.

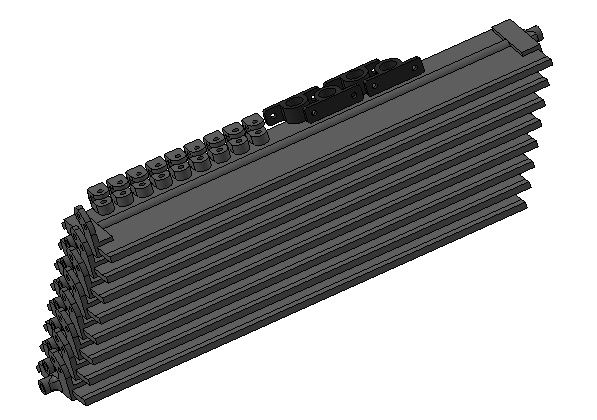

BTW, the above prices were based on sprued models: no loose parts, all connected together. If you don’t do that SW pings you extra for each separate “body,” no matter how small. For grins, here’s the pricing on part 1 with no sprues, all the parts loose.

Shapeways: $221

Jawstec: $58

Wow, almost a 4:1 diff! JT’s price didn’t go up with it being a multi-body part, so I don’t even need to mess with that tedious process, at least because of price. I might still though, to keep small parts together and not (as sometimes happens with SW) get lost in the process.

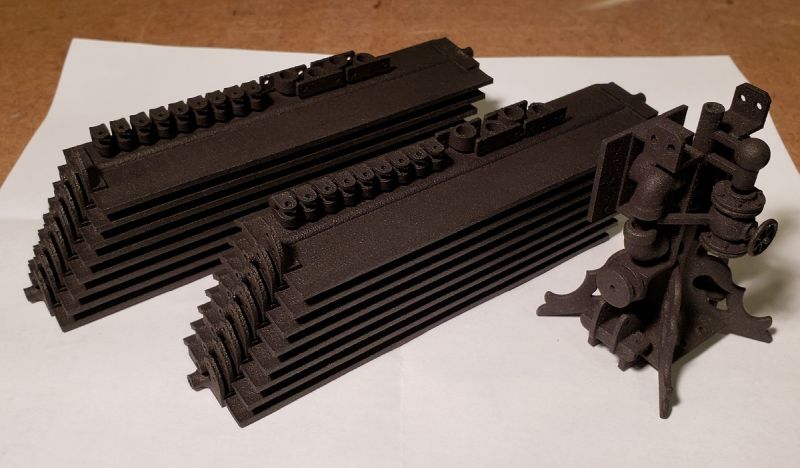

Here’s the part I’m talking about, all loose bits, about 6" long:

Cheers,

===>Cliffy