Just in the early stages in building outdoor structures.

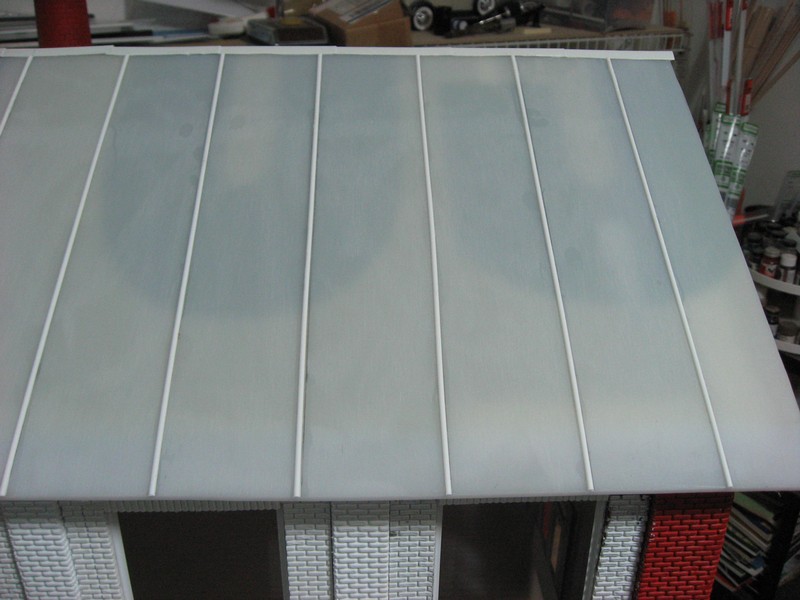

Been working on a single stall engine house built in redwood and now need to find a material for the roof. I was thinking of either using a Polycarbonate or Acrylic sheet as the base and then using aluminum pieces glued to it to have the desired effect.

Was thinking about 1/16 inch thick material.

What suggestions do folks have on suitable rooking material that will stand up and not easily chip?

Stan