Steve, Thank you, glad you find my efforts worthy of your time spent(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-laughing.gif)

As I said above these buildings are not designed to be out in wet weather conditions, they will take a shower or a little drizzle but not a continuous wetting like they will get here in Oregon over a whole winter.

I didn’t take any SBS picts for this project so here is a brief explanation of my steps on this.

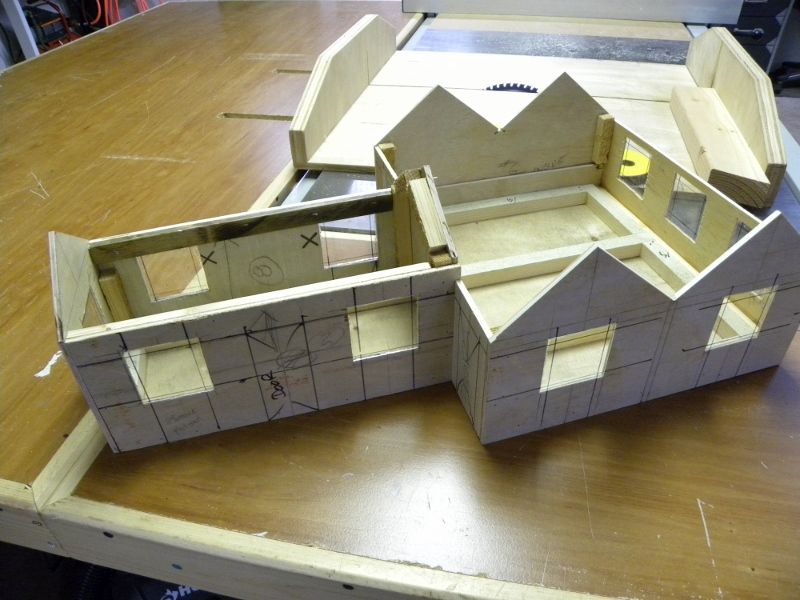

These are nothing more than 1/4 inch plywood boxes with blocking in the corners, glued and pinned, overlaid with 1/8 inch Cedar siding and roofing.

For windows if I want them to end up 1 3/4 inches square I cut out a hole in the wall 2 1/2 inches square and glue in a piece of Acrylic even with the outside. Then I glue the window trim at the 1 3/4 inches square on the Acrylic and the rest covers up with siding. This system helps me keep the messy gluing under control and off the “glass”, well sort of.(https://www.largescalecentral.com/externals/tinymce/plugins/emoticons/img/smiley-foot-in-mouth.gif)

Buildings like this with no interior finish I always fog the inside floor and walls with flat black paint to obscure the view through the windows.

All the siding and trim wood are ripped on my table saw from Western Red Cedar, the siding is attached with Liquid Nails and the trim with Tite Bond and small brads.

The roof on these was done with the Cedar strips then fogged with flat black paint then lightly sanded to represent “charred plank” roofing.

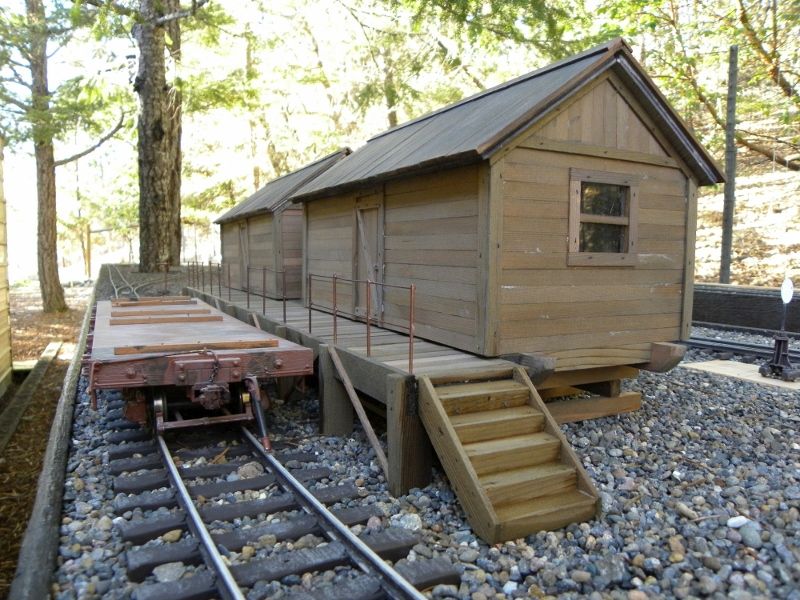

Size of the buildings are 11 foot wide by 24 foot long and the skids are 8’ wide by 28 foot long to fit a flat car.

I tried a new “stain” I found at home depot, it is a water base wood weathering in a gray color, the results, to me, are just so-so.

That’s about all I can think of, if you have any specific questions , fire away.

Rick

![]() , The Shasta Pacific Railroad is a wholly owned subsidiary of the South Fork Timber Co. I always show pictures of the Shasta Pacific but very seldom any of the Timber Co. so just wanted to clear that up.

, The Shasta Pacific Railroad is a wholly owned subsidiary of the South Fork Timber Co. I always show pictures of the Shasta Pacific but very seldom any of the Timber Co. so just wanted to clear that up.![]()