Best source for free crimping material is one’s favorite carbonated beverage can. Tools required - small lock back utility knife (Harbor Freight), small jeweler’s tin snips (Hobby Lobby), small square (min is 6"), straight edge (12"), and a pocket scribe (https://www.generaltools.com/mini-pocket-scriber). I also recommend finding a toaster oven that will do 500 degrees at a garage sale, I don’t believe the significant other till appreciate annealing the cans in the kitchen oven. I also use one similar to this https://www.thepaintstore.com/Marshalltown_Sponge_Float_p/4412.htm and a piece of 3/4" diameter copper pipe to back roll the cans after I cut them open.

The process I follow is: First I cut the side of the can top to bottom with the utility knife. Next I cut the top and bottom of the can off using the tin snips. Here is where I use the spackle sander and pipe to back roll the can stock to flatten it out some. Get the can to stick on the spackle sander curl up and roll across the pipe. Once I flatten the can stock some I place them in the toaster over (they can be stacked loosely) and ‘cook’ on 500 degrees for about an hour. This will anneal the aluminum making is softer and easier to run through the crimper. Once annealed, I recommend sanding the label side with sandpaper to give some tooth for the adhesive you will use later to attach to your structure.

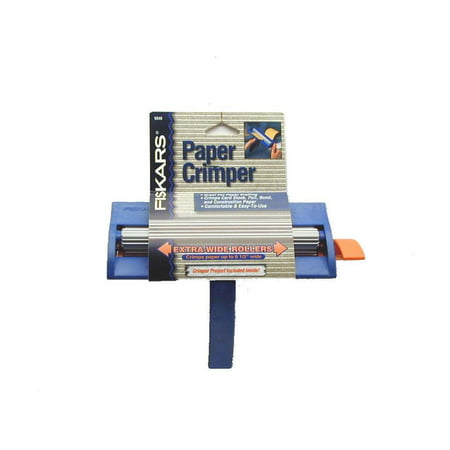

Your edges will be somewhat ragged and not too straight at this point. Take the long straight edge and your scribe and using fairly stout pressure scribe a line along one long edge of the can. Fold and back fold along this line until the can snaps, leaving a nice straight edge. Measure what will be the length of your panels from the clean edge and duplicate the process. Now use the 6" square and one of the straight edges and square one end of the material. Measure the width of your panels and repeat the scribing process to generate your ‘blank’ panels. Last step is to corrugate the panels with the crimper.

Hope this helps, and by the way, all of these processes are great brain dead stuff for in front of the TV. I have been known to cut up 50 cans in an evening watching the boob tube.