Ah, thank y’all. I’ve been a bit distracted today as this morning one of the 4 Davids in our little county seat farm burg’s model RR club called to say he found our location in basement of city council building flooded with up to about an inch and a half of water from what turned out to be a failed urinal flush valve. Our location used to be the Police Station and before that simply the basement of City Hall and before that a Post Office, IIRC

Of course it was deepest under my 16ft of the HO modular layout where I keep a bunch of supplies.

And I have some Bachmann tinplate G track on floor under yards in middle of HO modular layout.

I would add some pictures but Yahoo’s Flickr seems to be having issues at the moment.

Cleanup people picked up most of my stuff under the layout. That area by sink was said to be deepest water in main room, about an inch and a half David B said.

Ironically the floor drain is in a high spot in floor.

Looks like I’ll have to trash my cardboard and balsa G structures because of getting wet, I know there’s mold in the carpet because I’ve laid on it to nap, and you know it soaked in to the materials.  When building I’d soaked the cardboard and balsa with thinned lacquer so that apparently slowed down water absorption but the damage is done.

When building I’d soaked the cardboard and balsa with thinned lacquer so that apparently slowed down water absorption but the damage is done.

Also on floor were my G power packs.

Bachmann G power controller which likely got wet inside.My nice special edition MRC one from Hartland is sealed enough it was a non-issue for it with that water depth.

David B who discovered the flood around 7 am said water was to top of or just over ties on my G track. I need to know more, that rail is tinplate channel, not at all waterproof.

My G reefers are a non-issue, they are weather resistant.

I’m going to have to toss some boxes and instruction papers.

Fortunately my container of scenic supplies was at home.

And I had not left any of my blue Walmart bags of tools and supplies or my luggage for transporting HO trains, they were all at home.

Ah, now Flickr seems to be functional.

IMG_5181 by Forrest Wood, on Flickr

IMG_5181 by Forrest Wood, on Flickr

IMG_5186 by Forrest Wood, on Flickr

IMG_5186 by Forrest Wood, on Flickr

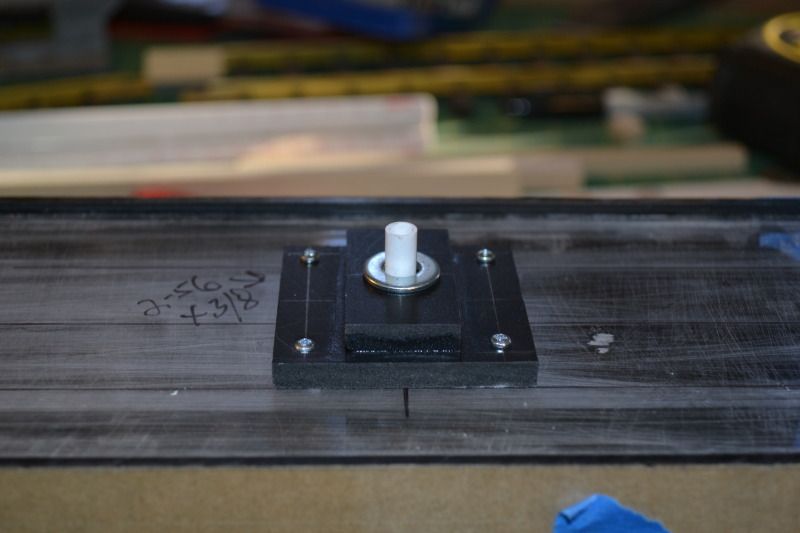

A picture from building the depot

IMG_5188 by Forrest Wood, on Flickr

IMG_5188 by Forrest Wood, on Flickr

IMG_5197 by Forrest Wood, on Flickr

IMG_5197 by Forrest Wood, on Flickr

IMG_5198 by Forrest Wood, on Flickr

IMG_5198 by Forrest Wood, on Flickr

IMG_5191 by Forrest Wood, on Flickr

IMG_5191 by Forrest Wood, on Flickr

IMG_5200 by Forrest Wood, on Flickr

IMG_5200 by Forrest Wood, on Flickr

IMG_5190 by Forrest Wood, on Flickr

IMG_5190 by Forrest Wood, on Flickr

IMG_5202 by Forrest Wood, on Flickr

IMG_5202 by Forrest Wood, on Flickr

Put above photo to left of one below.

This is my part of HO modular layout. Sink, cabinets, reefer, and hall to bathroom, are just out of frame lower left. With bathroom other side of wall at upper left of photo.

Track branching off lower left goes to another HO layout in rooms off bottom of photo.

IMG_4918 by Forrest Wood, on Flickr

IMG_4918 by Forrest Wood, on Flickr

IMG_5178 by Forrest Wood, on Flickr

IMG_5178 by Forrest Wood, on Flickr