The original bridge at Indian Hill was a simulated through girder made from a 3/4 plywood deck and 1/4" luan plywood sides with several coats of paint. It served me well for over 10 years, but rot has begun to take it’s toll and a falling branch took out a section of the side last fall.

I’ve decided to replace it with a deck girder bridge of the same design I used for West Es-cap’e several years ago. On the West Es-cap’e bridge, the bridge ties and guards were cut from PVC. This time I’m going to try Red Cedar. Recently at work I had prepped and painted three Red Cedar 5x5 posts for a sign install. Lucky for me, the posts I made were all too long. Two by about 20 inches and the other by at least a foot. The installer cut them in the field and brought me the scraps.

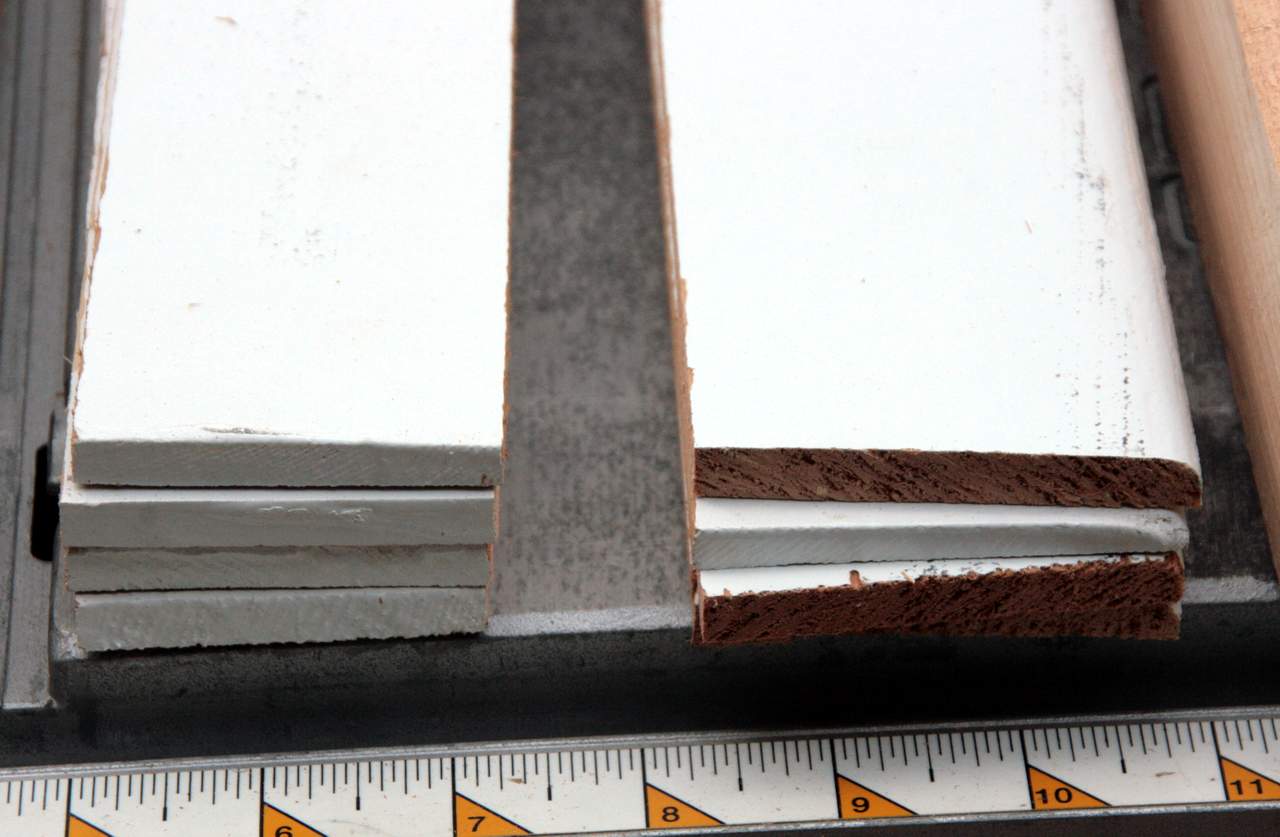

Today, the CVSRy Wood Shop was in full production turning these large chunks of Red Cedar into manageable pieces, bridge ties and guard timbers. First, the 5x5 chunks were quartered by running the through the table saw 4 times. The the two painted edges of each quarter was ripped off. Here’s the result…

Then, several quarters were sliced to 12mm thickness. Sample slices are at the left of this photo…

The slices were then ripped to 12mm square sticks…

Next, another quarter was sliced a bit thinner to be further ripped for guard timbers…

As you can imagine, this created quite the pile of sawdust…

There were a few smaller size sticks left over that I’ll use somewhere later shown at the left of this photo…

Then I set up my chop saw to cut the tie sticks(shut up Rooster) to length, 4 at a time…

After a few hours at the saw I had enough bridge ties and guard timbers for the eight foot bridge…

Next, I’ll start preparing the 2" square aluminum tube to simulate a welded girder.